Research

Biorefinery

Our research focuses on biomass fractionation to produce lignocellulosic feedstocks. We leverage our expertise in separation and chemical processing techniques to convert these feedstocks into high-purity furan and furan derivatives, enabling the sustainable production of bio-based chemicals.

Fractionation

Biomass is composed of three main components: cellulose, hemicellulose and lignin. These must be separated and isolated for subsequent processing methods suitable for each component. We focus on the development of cost-effective and scalable fractionation processes via chemical and physicochemical pretreatments. We have built liter-scale steam explosion reactors for the lab scale and continuous-flow liquid hot water reactors for the pre-pilot scale.

Several analytical tools are available in-house or nearby labs for exhaustive biomass characterizations:

- CHNS analyzers to determine elemental compositions

- High-performance liquid chromatography for sugar analysis

- Muffle furnaces for ash content analysis

- UV-Vis spectrophotometer for acid-soluble lignin (ASL) analysis

- FT-IR spectroscopy for identification of functional groups

- SEM for morphological studies

- Bomb calorimeter for energy content determination

Additionally, we are capable of analysis of the following standards related to biomass:

- ASTM

- NREL

Lignin

Lignin is a natural, aromatic polymer found in plant cell walls and a rich, renewable source of six-carbon (C6) aromatic compounds. These compounds offer a sustainable alternative to petroleum-derived C6 aromatics, such as benzene, toluene, and xylene (BTX), which are essential for producing chemicals, fuels, and materials. Our research focuses on the selective depolymerization of lignin to produce high-value C6 aromatic monomers and other chemical precursors, advancing the transition to a circular bioeconomy and reducing dependence on fossil resources.

Furan-based chemicals

Furan-based chemicals are versatile, bio-derived molecules that serve as key building blocks for sustainable chemistry. Derived from renewable resources like agricultural residues, they play a pivotal role in producing bio-based plastics, fuels, and specialty chemicals.

Our research explores cutting-edge advancements in:

- Thermochemical and electrochemical synthesis of furan-based chemicals and derivatives, including furfural, 5-hydroxymethylfurfural (HMF), 2,5-furandicarboxylic acid (FDCA), 2,5-bis(hydroxymethyl)furan (BHMF), 2,5-diformylfuran (DFF), and furan-2,5-dicarboxylate (FDMC).

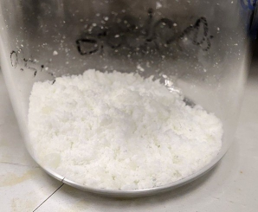

- Advanced separation and purification techniques, such as reactive extraction, advanced distillation, absorption, lyophilization, and preparative chromatography.

- Innovative applications for bio-based products, including furan-based plastics and plasticizers.