Meta description (140–160): Quantify surface area and porosity of powders with NANOTEC’s BET analysis—reporting specific surface area, pore size diameter, and pore volume to guide formulation, supplier control, and performance troubleshooting.

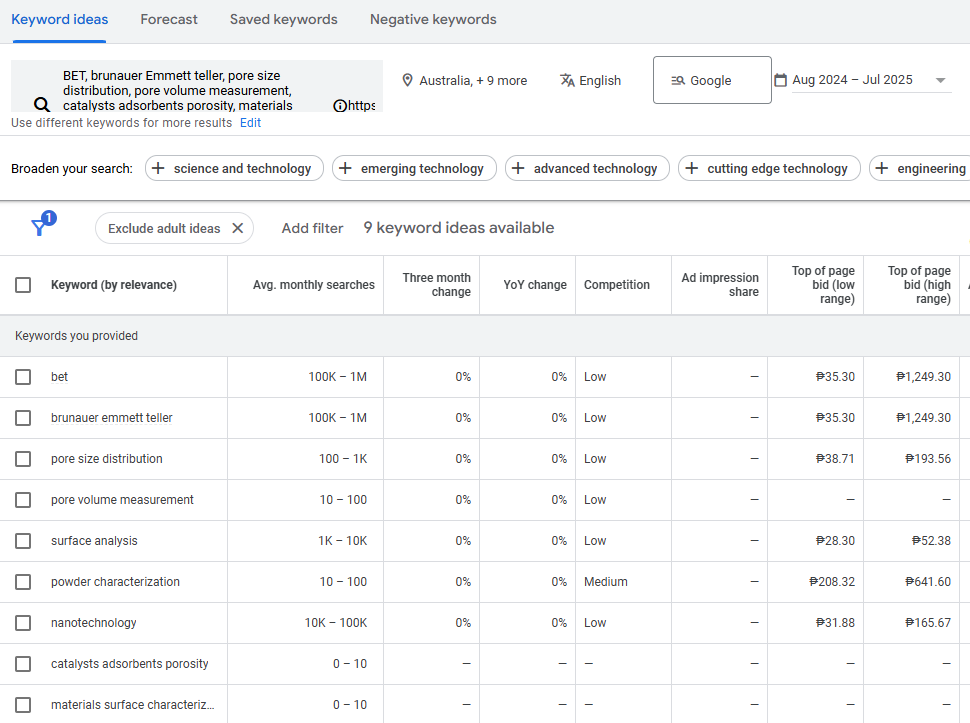

SEO Keywords (one line): BET, brunauer Emmett teller, surface analysis, pore size distribution, nanotechnology, pore volume measurement, powder characterization, catalysts adsorbents porosity, pigments fillers cosmetics, ceramics battery powders, materials surface characterization, packaging and film additives, environmental media testing

Why BET Matters

When your product begins as a powder—catalysts, adsorbents, pigments, fillers, ceramic or battery precursors—its performance is governed by how much surface is available and how that surface is organized into pores. Specific surface area affects reaction rates, adsorption capacity, binder interaction, and dispersibility. Pore size and pore volume shape solvent uptake, capillary transport, flow and packing, and how additives wet and anchor to particles. Two materials with the same sieve cut or similar laser-diffraction size curves can behave very differently in a mill, a coating, or a reactor because their internal surface architecture is different.

NANOTEC’s BET Surface Area & Porosity service translates those hidden properties into clear, quantitative numbers you can use. The data are valuable across the product lifecycle: qualifying incoming lots, tuning activation or milling, diagnosing batch-to-batch drift, and documenting specifications for customers and auditors. Testing is delivered within our ISO 9001 quality framework and can be bundled with complementary techniques—E-SEM/AFM for morphology and nano-texture, Contact Angle for wettability of pressed pellets, and DLS for in-liquid particle size—so that decisions are driven by a coherent, multi-method dataset rather than a single number in isolation.

How BET Works, Turning Adsorption Into Surface Metrics

The Brunauer–Emmett–Teller (BET) method is a gas adsorption technique. Under controlled temperature and pressure, an inert adsorptive gas physisorbs onto the accessible surface of a solid. By measuring the adsorbed volume across a range of relative pressures and fitting the BET model to the linear region of the isotherm, we estimate the monolayer capacity and calculate specific surface area (m²/g). When pore characterization is appropriate, additional analysis of the adsorption–desorption isotherm provides pore size (diameter) and pore volume—particularly informative for mesoporous materials.

In practice, BET gives you:

- A distinction between high- and low-area lots even when bulk particle sizes look similar.

- Insight into how activation, calcination, or milling change porosity and surface exposure.

- Explanations for dispersion differences and unexpected viscosity or opacity shifts in coatings, inks, and slurries.

- A common language to align R&D, QA, procurement, and customers on what “similar powder” really means.

Because the method responds to the accessible surface, it is highly relevant to real processes—what the adsorptive gas can reach, solvents and binders often can too.

What We Measure and When to Use It

Primary outputs

- Specific surface area (m²/g)

- Pore size (diameter)

- Pore volume

Use BET when you need to:

- Qualify suppliers and set acceptance limits for catalytic/adsorbent media, pigments, or fillers.

- Tune processing steps—milling, granulation, activation, calcination—and verify their effect before committing to scale.

- Correlate performance (adsorption capacity, reaction rate, opacity, texture, flowability) with measured surface parameters.

- Troubleshoot deviations in mixing, dispersion stability, or packing density that trace back to changes in internal surface.

- Document specs for customers and auditors with quantitative, reviewable metrics.

Typical materials we support

- Catalysts & adsorbents (activated carbons, alumina, zeolites, MOFs)

- Pigments & fillers (TiO₂, silica, talc, CaCO₃) for cosmetics, coatings, plastics

- Ceramic & battery powders (e.g., LFP/NMC precursors, alumina/zirconia)

- Functional/food powders (encapsulates, carriers)

- Environmental media (filter beds, ion-exchange resins/media)

If you need context beyond “how much surface?”, pair BET with E-SEM to visualize particle edges and agglomeration, AFM to quantify nano-texture on pressed films, Contact Angle to assess wettability of compacted surfaces, or DLS to connect powder properties to slurry or ink behavior.

Instrumentation & Sample Requirements

BET analyses at NANOTEC are performed on a Micromeritics 3Flex surface area and porosity analyzer—suited to research and industrial powders alike.

- Instrument: Micromeritics 3Flex (BET/surface area and porosity)

- Sample type: Powders

- Minimum sample amount: ≥ 1 gram

- Typical preparation: Degassing ~12 hours at 150 °C (adjusted if your material is heat- or vacuum-sensitive)

We choose degassing conditions to remove adsorbed moisture and volatiles without altering the surface. If your powder contains binders, residual solvents, or thermally labile components, please disclose that at booking; we will align the protocol to protect the material while achieving reliable results.

Reporting You Can Use

Decision-makers need clarity, not raw dumps. A standard BET report from NANOTEC is structured so you can file it directly in QA systems or customer packages:

- Specific surface area (m²/g) with model/fit details

- Pore size (diameter) and pore volume when applicable

- Isotherm summary (plots and the pressure range used for analysis)

- Method summary—preparation/degassing conditions and any relevant notes on handling

- Comparative table for multiple lots or process conditions (on request)

- Interpretive notes linking results to likely formulation or performance implications

If your organization uses house templates or needs bilingual outputs, we can align format, headings, and terminology to your documentation standard.

How BET Data Drives Better Decisions

1) Incoming Quality Control (IQC)

BET provides a quick, quantitative screen alongside particle size and moisture. You can reject or quarantine lots that fall outside surface area or pore volume windows, long before they compromise throughput or product quality.

2) Process Development & Scale-up

Adjust activation temperature/time, atmosphere, or milling parameters and immediately see whether your surface area and porosity land in the target window. This closes the loop between process settings and functional outcomes—reducing guesswork during scale-up.

3) Troubleshooting & Failure Analysis

When a catalyst underperforms, a coating thickens, or a tablet caps, BET helps confirm whether a surface-related shift (loss of area, pore collapse, blocked pores) is responsible. Pair with E-SEM to visualize structural changes that explain the numbers.

4) Customer & Regulator Communication

BET metrics are widely understood in catalysis, adsorption, ceramics, and pigments. Publishing surface area and pore data in your technical data sheets and COAs builds trust, aids audits, and reduces iterative Q&A with downstream users.

Sample Guidance, Getting Reliable BET Results

BET is sensitive to surface cleanliness and pre-adsorbed volatiles. Appropriate preparation prevents misleading numbers and improves repeatability.

- Keep powders dry. Provide sealed containers; minimize exposure to ambient humidity before submission.

- Share history. Note milling/activation/calcination steps and storage conditions; context improves interpretation.

- Representativeness matters. For heterogeneous lots, supply a composite or multiple subsamples; mark any known lot IDs.

- Tell us about sensitivities. If the powder is moisture- or heat-sensitive, or contains binders that evolve under heat/vacuum, we will adjust degassing (time/temperature) accordingly.

- Safety. Disclose hazards (fine dust, reactive powders, adsorbed organics). Our team will ensure appropriate handling, ventilation, and waste procedures.

Minimum quantity: ≥ 1 g supports method checks and repeat points without exhausting your material. If your powder is scarce or precious, let us know and we can optimize the protocol to conserve sample while meeting quality thresholds.

Method Considerations & Good Practices

- Analysis window. We select the linear region of the isotherm for BET fitting; reporting includes the relative pressure range used and any consistency checks (e.g., C constant reasonableness).

- Non-porous vs. porous. For non-porous or low-porosity powders, specific surface area is the main discriminant. For mesoporous systems, we can add pore size/volume analysis based on the adsorption–desorption isotherm.

- Comparability. For supplier or process comparisons, consistency in preparation (degassing protocol) and analysis settings ensures that differences reflect the material rather than the method. We maintain those controls and document them in the report.

- Linking to performance. Surface area is not the whole story. If your process depends strongly on wettability, particle shape, or nano-texture, combine BET with Contact Angle, E-SEM/AFM, and DLS for a more causal picture.

Where BET Fits in Your R&D and QC Workflow

- Design of Experiments (DoE). Use BET as a response variable when screening activation profiles or milling recipes; uphold statistical power with planned replicates.

- Formulation windows. Define acceptable bands of surface area/pore volume for pigments, fillers, or active carriers so viscosity, opacity, or texture remain in spec.

- Supplier management. Require BET certificates for critical powders and verify through periodic third-party checks at NANOTEC; maintain an image + BET library (E-SEM + BET) for robust onboarding of alternates.

- Change control. Any proposed change to raw material, vendor, or process can be risk-assessed against BET (and companion methods) before full adoption.

Choosing Complementary Methods (When One Number Isn’t Enough)

- E-SEM (Environmental SEM). Visualize particle edges, agglomerates, fractures, and surface features to explain dispersion or packing behavior. E-SEM is excellent for non-conductive powders with minimal coating.

- AFM (Atomic Force Microscopy). Map nanoscale texture/roughness on pressed pellets or compacted films; useful when tactile feel or adhesion depends on topography.

- Contact Angle & Surface Energy. Evaluate wettability of pressed pellets or coated substrates—key for adhesion, ink laydown, cleanability, and slurry behavior.

- DLS (Dynamic Light Scattering). If your powder becomes a dispersion, DLS quantifies in-liquid particle size and zeta potential, linking powder properties to slurry or ink performance.

Together, these methods produce a coherent, multi-method dataset that explains not just what changed, but why and how to fix it.

Who This Service Is For

- Catalyst & Adsorbent Producers (Corporate/OEM). You need consistent activity and uptake. Use BET to control activation, compare suppliers, and document specifications that customers trust.

- Cosmetics, Coatings & Plastics (Pigments/Fillers). Opacity, viscosity, and feel depend on surface and porosity. BET helps tune milling or surface treatment and set realistic incoming QC limits.

- Ceramics, Electronics & Energy Materials. Sintering behavior and electrochemical performance track with specific surface area and pore structure; BET supports process windows that protect yield and performance.

- Environmental & Water Treatment Media. Capacity and kinetics are surface-driven. BET provides a quick health check before media goes into service or to compare regeneration cycles.

- SMEs & Tech Startups. Before scaling, use a lean BET panel to validate supplier claims and correlate lab performance with measured surface parameters—without building in-house capability.

Turnaround & Scheduling

BET schedules reflect two realities: lab throughput and sample preparation time. The largest contributor is degassing (often ~12 hours at 150 °C) to remove adsorbed water/volatiles without altering surface chemistry.

- Planning note: If you have tight timelines or many lots, tell us at booking. We’ll sequence degassing and runs to deliver decision-ready numbers as quickly as method quality allows.

- Multi-method projects: If you are combining BET with other services (e.g., microbiological tests that require four consecutive working days), we will stage the program so that BET results arrive early and holiday schedules do not break critical test windows.

Pricing Overview

Use the guide price to scope your program; we’ll confirm a formal quotation based on sample count, repeated runs, and reporting depth.

- BET surface area & porosity (powders): from THB 2,000 per item

- Options: multi-lot comparisons, extended notes/annotations, isotherm plots in the appendix, bundled methods (e.g., BET + E-SEM morphology; BET + Contact Angle on pressed films; BET + AFM for nano-texture)

Frequently Asked Questions (recap)

What does BET actually tell me?

It quantifies specific surface area and, where applicable, estimates pore size and pore volume—the parameters that drive adsorption, reaction rates, and dispersion behavior.

Can non-porous powders benefit from BET?

Yes. Even without intentional porosity, specific surface area influences how powders wet, bind, and pack—critical for coatings, tablets, and ceramics.

Do samples need to be dried or degassed?

Often, yes. Preparation is tailored to your material to remove adsorbed moisture or volatiles without altering the surface. Share your material’s sensitivities so we choose appropriate conditions.

Can I compare suppliers or batches directly?

Yes. Side-by-side BET results (surface area, pore size/volume) make differences clear for QA and procurement and often explain observed processing differences.

How do I link BET results to performance?

Combine BET with morphology (E-SEM), nano-texture (AFM), wettability (Contact Angle), or chemistry (FTIR/Raman) to build mechanistic understanding and set robust specs.

Suggested Internal Links (provisional; finalize later)

- E-SEM — Morphology & Image-Based Sizing

- AFM — Nanoscale Surface Topography

- Contact Angle — Wettability & Surface Energy

DLS — Particle Size & Zeta Potential

Contact & CTA

Request a BET analysis or book a consultation to design the right powder characterization plan. We will deliver clear numbers and practical guidance you can use in R&D, QC, and customer documentation—and recommend complementary methods when a single metric isn’t enough..

Infrastructure Services

National Nanotechnology Center (NANOTEC)

143 INC 2 (B), Thailand Science Park, Phahonyothin Road, Khlong Nueng, Khlong Luang, Pathum Thani 12120

Tel. +66 2 564 7100 ext. 6517, 6625, 6680

Email: bdis-infs@nanotec.or.th