Meta description (140–160): Accelerate sunlight exposure with NANOTEC’s Q-SUN weathering test—full-spectrum UV-Visible-IR plus controlled humidity to assess fading, yellowing, cracking, and durability across coatings, plastics, textiles, and packaging.

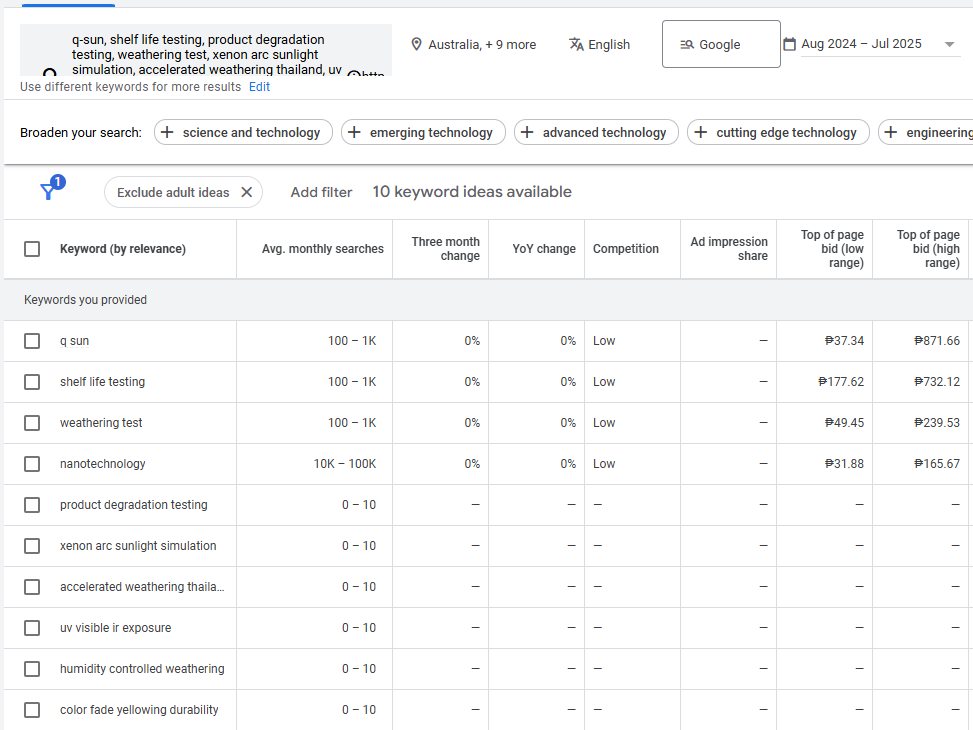

SEO Keywords: q-sun, shelf life testing, nanotechnology, product degradation testing, weathering test, xenon arc sunlight simulation, accelerated weathering thailand, uv visible ir exposure, humidity controlled weathering, color fade yellowing durability, coatings plastics textiles packaging, cosmetics packaging testing, electronics enclosure aging, materials performance Thailand

Why Q-SUN Weathering Matters

Sunlight and moisture quietly shape product reality. Coatings chalk or crack, polymers yellow and embrittle, inks fade, labels curl, and packaging loses legibility—often months after launch if durability isn’t proven up front. These failures lead to warranty claims, shelf-appeal losses, and expensive reformulation under time pressure.

NANOTEC’s Q-SUN accelerated weathering compresses months of outdoor or shelf exposure into a practical lab schedule. Using a xenon-arc light source that reproduces the full solar spectrum (UV, Visible, IR) with controlled humidity, we surface the earliest signs of color change, gloss loss, micro-cracking, and adhesion issues—before they show up in the field. The result is a faster path to evidence-based specifications, more confident supplier qualification, and fewer surprises after scaling.

Because the Q-SUN sits inside NANOTEC’s broader lab ecosystem (e.g., FTIR/Raman for chemical changes, DSC for thermal limits, E-SEM/AFM for surface morphology), once an exposure reveals a weakness we can immediately move to root-cause diagnostics—no vendor juggling required.

Key Highlights (at a glance)

- Method: Xenon-arc Q-SUN weathering (UV-Visible-IR) with humidity control

- What you learn: Δcolor (fading/yellowing), gloss loss, chalking/cracking, label/print durability, adhesion/coating integrity

- Typical specimens: Coated panels, polymer films, plastic parts, labels/inks on packaging, textiles, painted or printed substrates

- Pricing: from THB 650 per hour of exposure

- Reporting: Photos + observational notes at intervals, final summary vs your acceptance criteria

- Follow-ups: On-the-spot diagnostics available (FTIR/Raman, E-SEM/AFM, DSC) when issues are detected

What the Q-SUN Doe and When to Use It

Full-spectrum sunlight + humidity. The Q-SUN chamber exposes your samples to a calibrated xenon-arc source that covers UV, Visible, and IR, while the chamber maintains controlled humidity. By tuning irradiance, temperature, and wet/dry cycles, we create accelerated yet realistic conditions that drive photo-oxidation, dye fade, plasticizer loss, and moisture-assisted degradation.

Evaluate and compare:

- Color/appearance change — fading, yellowing, ΔE, print density loss

- Surface degradation — chalking, micro-cracks/crazing, gloss loss, haze

- Mechanical indications — early embrittlement, flake/peel onset, stress whitening

- Label & print durability — legibility, curl, adhesion of inks/varnishes on films and packs

- Coating/adhesive integrity — adhesion under light + moisture cycles; edge lift and blister checks

Use Q-SUN weathering to:

- Screen formulations and pigments before pilot runs

- Qualify suppliers with side-by-side exposure on identical schedules

- Benchmark packaging for cosmetics, food, and electronics under retail and logistics conditions

- Correlate exposure hours to acceptance thresholds in your internal specs and customer SLAs

- Troubleshoot field returns by replicating service stressors and documenting the failure path

If you need UV-only emphasis (isolating spectral effects), pair this service with QUV testing. For thermal-only limits (no light), DSC establishes safe processing and storage windows.

Instrumentation & Sample Requirements (Q-SUN)

Weathering tester

- Q-LAB Q-SUN XE-3 xenon-arc Photostability/Weathering oven (sunlight simulation + humidity)

Accepted sample types & size

- Typical substrates: Polymer and metal panels or parts (coated, printed, or bare)

- Standard panel size: 11 × 7.5 cm (approx.)

Have larger or unusual parts (films, textiles, labels)? We can advise on mounting or panelization so the exposed area is consistent and meaningful.

Test duration

- Exposure time depends on your target hours and the decision you need (screening vs. qualification). We’ll help right-size the schedule and define inspection intervals so you can stop once outcomes are clear.

Test Planning & Typical Outputs

We design exposures to answer your question efficiently—enough stress to make differences visible, not so much that you miss the window when issues first emerge.

A typical plan includes:

- Exposure profile — target total hours, humidity setpoints, and any wet/dry or dark cycles aligned to your material class.

- Inspection cadence — agreed checkpoints (e.g., every 100–200 hours) for photos and observational notes.

- Comparative layout — if you’re evaluating multiple formulations or suppliers, we mount them in parallel to eliminate schedule bias.

- End-point review — a concise summary of observed changes (e.g., first onset of yellowing, micro-crack appearance, gloss drop) vs. your acceptance criteria.

Your report can include:

- Photographic evidence at each interval (consistent lighting/angles for comparability)

- Observational notes on color shift, chalking, micro-cracks, print density loss, curl/peel

- Pass/fail flags relative to your criteria (provide thresholds where available)

- Recommendations for diagnostic follow-ups (e.g., FTIR for oxidation markers, E-SEM for crack morphology, DSC if softening is implicated)

Where helpful, we add side-by-side plates and overlay charts so stakeholders can grasp differences in seconds.

Sample Preparation & Handling (How to Get Reliable Results)

Weathering data is only as good as the samples and mounting. A few practical guidelines:

- Representativeness. Send production-grade substrates—coated panels, molded parts, printed labels, laminated films, textiles—that mirror your real process.

- Dimensions & edges. When possible, provide 11 × 7.5 cm flat panels; for parts or films, we’ll discuss panelization or clip mounting to present a consistent exposed area.

- Orientation & side marking. Indicate front (print) side, top/bottom orientation, and any masking requirements (e.g., to simulate edge protection).

- Cleanliness. Avoid fingerprints, oils, or dust; residues can trigger early discoloration or adhesion loss.

- Baselines. If you track ΔE, gloss, or haze in-house, share methods so checkpoints align with your metrics.

- Safety. Disclose volatiles, odors, or sensitive additives that may influence chamber handling or require special precautions.

- Replicates. If you need statistical confidence, send duplicates/triplicates so results aren’t driven by a single specimen.

If your program includes post-exposure testing (e.g., cross-hatch adhesion, tensile, FTIR), let us know upfront so we reserve enough material and sequence the workflow.

Where Q-SUN Fits in Your Development & QC Workflow

R&D screening. Rapidly down-select pigments, stabilizers, and binders. Rather than waiting for field data, you can watch when changes begin and rank candidates by onset hour.

Supplier qualification. Expose materials from multiple vendors under the same regimen. Document which one holds color, gloss, and adhesion longer; use the evidence to set incoming QC acceptance limits.

Production troubleshooting. If field returns cite fading or print loss, replicate stressors and observe the failure path. Then use FTIR/Raman (oxidation markers, additive loss) and E-SEM/AFM (micro-crack texture) to pinpoint cause and fix it.

Regulatory/customer files. Provide exposure conditions, interval photos, and observations as part of your quality dossier—especially useful for overseas partners who expect standardized documentation.

Who This Service Is For

- Coatings, Films & Packaging (Corporate / OEM/ODM). Establish sunlight/humidity durability for clear coats, color coatings, laminates, and printed packs; compare suppliers side-by-side to support sourcing decisions.

- Cosmetics & Personal Care Packaging (Brands & Converters). Verify color stability of bottles/caps, label legibility, and finish integrity under retail and sun-adjacent storage; protect shelf appeal across climates.

- Plastics & Textiles. Assess yellowing, fading, and embrittlement risks for outdoor, window-adjacent, or high-light environments; set exposure-hour targets that map to intended lifetimes.

- Electrical & Electronic Enclosures. Confirm color shift and surface cracking resistance on polymer housings exposed to heat/light in service; align results with reliability claims.

- SMEs & Tech Startups. Start lean with screening exposures, then scale to qualification once a formulation path is clear.

- Universities & Research Institutes. Generate publication-ready exposure evidence and link it to material chemistry and microstructure without changing labs.

- Overseas Customers/Investors. Receive standardized, clearly annotated reports suitable for partner review and procurement files.

Choosing Complementary Methods (When “It Faded” Isn’t Enough)

- QUV (UV Weathering). When you want UV-centric aging to isolate spectral effects apart from the full solar spectrum.

- DSC (Thermal Analysis). Map melting/softening and decomposition onsets—useful when heat, not light, is suspected.

- FTIR / Raman. Identify oxidation, additive loss, or photo-chemical changes underlying yellowing or brittleness.

- E-SEM / AFM. Visualize micro-cracks, chalking, or surface texture evolution post-exposure.

- Contact Angle. Check how weathering alters wettability/adhesion for coatings, inks, or cleanability.

Together these tools transform surface observations into root-cause narratives you can act on.

Pricing Overview

Use the guide rate to scope your program; we’ll confirm a formal quotation based on total exposure hours, inspection intervals, number of variants, and reporting depth.

- Q-SUN weathering (sunlight + humidity): from THB 650 per hour

- Options: interval photo sets & notes, multi-formulation/supplier layouts, post-exposure diagnostics (FTIR, E-SEM/AFM, DSC), bundled QUV runs

If you’re coordinating multiple tests across services, we can phase early checkpoints so you see actionable signals while longer exposures continue.

Frequently Asked Questions (recap)

What does the Q-SUN simulate?

The full sunlight spectrum (UV, Visible, IR) with humidity control, enabling accelerated yet realistic weathering.

What outcomes are typically assessed?

Color/appearance change (fading, yellowing), gloss loss, chalking/cracking, print/label durability, and early signs of embrittlement or adhesion loss.

How many hours should I run?

It depends on the material and decision. We’ll propose a practical exposure hour target and interval checks; you can stop once outcomes are clear.

Can you compare suppliers or colors side-by-side?

Yes. We mount variants in parallel and inspect them on the same schedule so differences are unambiguous for QA and procurement.

What if exposure reveals a failure?

We can immediately add diagnostic tests—FTIR/Raman for chemical change, E-SEM/AFM for micro-cracks, DSC for softening—to identify cause and recommend changes.

Suggested Internal Links

- Thermal Analysis — DSC (Differential Scanning Calorimetry)

- Shelf-life & Product Degradation — QUV (UV Weathering)

Contact & CTA

Request a Q-SUN weathering plan or book a consultation to design the right sunlight + humidity exposure for your materials. We’ll deliver clear evidence you can use for R&D screening, supplier control, QC, and customer documentation.Infrastructure Services

National Nanotechnology Center (NANOTEC)

143 INC 2 (B), Thailand Science Park, Phahonyothin Road, Khlong Nueng, Khlong Luang, Pathum Thani 12120

Tel. +66 2 564 7100 ext. 6517, 6625, 6680

Email: bdis-infs@nanotec.or.th