Meta description (140–160): Predict UV-driven fading, yellowing, and cracking with NANOTEC’s QUV accelerated weathering—UV exposure programs to screen and qualify coatings, plastics, textiles, and packaging before they reach the field.

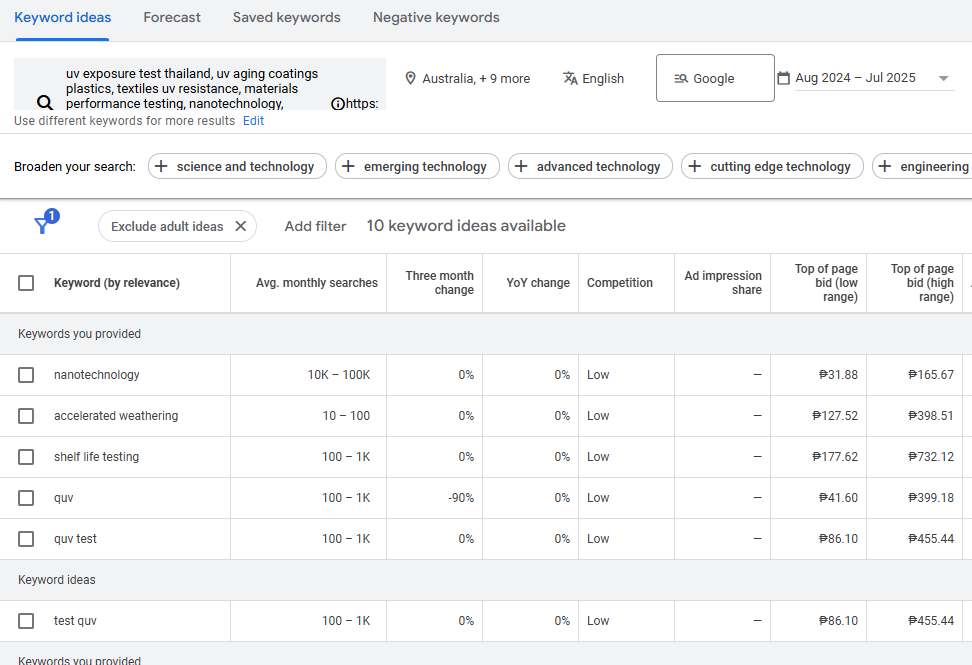

SEO Keywords: quv, quv uv, shelf life testing, product degradation test, quv test, uv accelerated weathering, uv exposure test thailand, uv aging coatings plastics, color fade yellowing uv, gloss loss chalking, packaging label uv stability, roofing materials durability, textiles uv resistance, cosmetics packaging uv test, materials performance testing

Why QUV Matters

Ultraviolet (UV) radiation is the quiet driver behind countless quality problems: colors fade, clear plastics yellow, glossy surfaces turn chalky, and polymer parts lose toughness at their exposed edges. These changes often appear months after launch—too late to correct without expensive recalls or reformulations. QUV UV accelerated weathering isolates the UV component of sunlight so you can see UV-specific failure modes early, compare supplier lots with evidence, and set acceptance criteria that protect appearance, function, and warranty claims.

At the National Nanotechnology Center (NANOTEC), QUV runs are tightly integrated with follow-on diagnostics. When exposure reveals a weakness, we can immediately characterize chemical shifts (FTIR/Raman), thermal limits (DSC), or micro-crack morphology (E-SEM/AFM). That means shorter cycles between finding a problem and fixing the cause, without changing labs or vendors.

Key Highlights (at a glance)

- Method focus: UV-only accelerated weathering to isolate photo-oxidation effects

- What you’ll learn: Onset and progression of fading, yellowing, gloss loss, chalking, micro-cracking/crazing, and print/label durability under UV

- Ideal for: Coatings, plastics, textiles, printed/labelled packaging, roofing/outdoor materials, cosmetics packaging, electronic enclosures

- Comparisons: Side-by-side supplier/formulation panels under identical UV regimens

- Deliverables: Interval photos + notes, end-point summary vs. your acceptance criteria, recommendations for root-cause diagnostics

- Scheduling: Exposure hours tailored to your decision need (screen vs. qualification)

What the QUV Does—and When to Use It

UV exposure to accelerate photodegradation.

Our QUV chamber concentrates on the UV portion of sunlight, the dominant stressor behind photo-oxidation in polymers, inks, and coatings. By applying controlled UV irradiance (and, where required, condensation/spray cycles), QUV reproduces many long-term UV effects in a compressed timeframe—ideal when you want to separate UV damage from broader sunlight (visible/IR) and humidity interactions.

Use QUV to evaluate:

- Color/appearance change: fading, yellowing, loss of chroma; compatibility across colorways

- Surface degradation: gloss loss, chalking, early micro-cracking/crazing

- Labels & prints: ink/varnish legibility, adhesion, and curl under UV

- Polymer embrittlement indicators: visual cracks at stress concentrators, whitening at radii/edges

Choose QUV when you need UV-only insight for screening, supplier comparisons, or qualification against UV durability specs.

Choose Q-SUN when full UV + Visible + IR (sunlight) with humidity better represents real service conditions (we can run both and compare).

Instrumentation & Sample Requirements (QUV)

UV accelerated weathering tester

- Q-LAB QUV/spray (UV accelerated weathering tester)

Accepted sample types & size

- Substrates: Polymer and metal panels/parts (coated, printed, or bare)

- Standard panel size: 11 × 7.5 cm (approx.)

Have films, textiles, labels, or larger parts? We’ll advise on panelization or mounting so your exposed area is representative and comparable.

Test duration

- Driven by your target exposure hours and decision need; we’ll propose intervals for inspection so you can stop once outcomes are clear.

Test Planning & Typical Outputs

Every program begins with your decision goal—quickly rank options or qualify a candidate for release. We design the exposure to reach that decision efficiently.

Plan elements (example):

- Exposure schedule: total UV hours with interval inspections (e.g., every 100–200 hours)

- Chamber settings: [Insert: lamp/spectrum program and any condensation/spray if required by your standard]

- Panel layout: parallel mounting for side-by-side supplier/formulation comparisons

- Checkpoints: standardized photographs and observational notes at each interval

- End-point review: concise summary vs. your acceptance criteria (ΔE/gloss thresholds, visual standards)

Reporting package:

- Before/after and interval photos under consistent lighting/angles

- Observational notes: first evidence of yellowing, onset of chalking/cracks, gloss change, print density loss

- Pass/fail flags against your criteria (share limits if you have them)

- Method summary: key UV settings, inspection schedule, any condensation/spray usage

- Recommendations: targeted diagnostics (e.g., FTIR for oxidation markers, E-SEM for crack morphology) or exposure adjustments

If you require a standards-aligned protocol (e.g., specific industry methods), share the reference; we’ll align documentation accordingly.

Sample Preparation & Handling (How to Get Reliable Results)

Robust exposure data depends on representative specimens and clean handling.

- Send production-grade samples: coated panels, molded parts, printed labels/films, textiles, or cut coupons matching your real process

- Mark the test side (coated/printed face) and note any orientation requirements

- Avoid contamination: fingerprints, oils, dust, or release agents can bias early discoloration or adhesion outcomes

- Retain a control: keep a same-lot specimen for post-test comparisons or analytics

- Disclose sensitivities: volatiles/odors, adhesive types, or heat-sensitive elements that may affect mounting and chamber handling

- Plan for diagnostics: if you anticipate post-exposure tests (adhesion, FTIR/Raman, microscopy), tell us so we allocate material and schedule in sequence

Where QUV Fits in Your Development & QC Workflow

R&D screening. Rank candidate pigments, stabilizers, binders, or coating recipes. Identify which variants hold color and gloss longer under the same UV stress.

Supplier qualification. Mount competing lots side-by-side, expose on the same schedule, and quantify differences. Use the evidence to set incoming QC limits or update supplier scorecards.

Production troubleshooting. Replicate field complaints—fading, label failure, gloss drop—to confirm mode. Then connect outcomes to chemistry (FTIR/Raman) or micro-structure (E-SEM/AFM) to recommend actionable process/formulation changes.

Customer/retailer documentation. Provide objective UV exposure evidence to support claims, datasheets, and shelf-life guidance, including photographic plates and method summaries.

Who This Service Is For

- Coatings, Films & Packaging (Corporate / OEM/ODM). Set UV durability specs for clear coats, colored coatings, laminates, labels, and printed packs; compare suppliers side-by-side before committing.

- Plastics & Outdoor Materials (Roofing, Enclosures, Profiles). Gauge yellowing, gloss loss, and embrittlement risks to protect appearance and function in high-UV environments.

- Textiles & Inks. Evaluate colorfastness and print endurance under UV to prevent early fade or legibility loss in service.

- Cosmetics & Personal Care Packaging. Ensure bottles, caps, and labels maintain color and legibility under shelf lights and sunlight-adjacent conditions.

- SMEs & Tech Startups. Start with lean screening to pick a direction; move to qualification once a formulation path is clear.

- Universities & Research Institutes. Generate publication-ready exposure evidence paired with analytical follow-ups in the same facility.

Choosing Complementary Methods (When “It Faded” Isn’t Enough)

- Q-SUN (Sunlight + Humidity): full-spectrum UV + Visible + IR with humidity cycles for broader sunlight simulation.

- FTIR / Raman: detect photo-oxidation and additive depletion behind yellowing/gloss loss.

- E-SEM / AFM: visualize micro-cracks, chalking, and nano-texture evolution post-UV.

- Contact Angle: see how UV aging changes wettability and cleanability (important for coatings/films).

- DSC: define thermal windows (melting/softening, decomposition) independent of UV to avoid heat-related damage during processing.

Together, these tools build a root-cause narrative—from exposure → chemistry → structure → performance.

Pricing Overview

Use these bullets to scope your program; we’ll finalize a formal quotation after confirming exposure hours, inspection intervals, and reporting depth.

- QUV UV accelerated weathering: [Insert: starting price] per hour

- Options: interval photo documentation; multi-formulation/supplier comparisons; post-exposure diagnostics (FTIR/E-SEM/AFM); combined QUV + Q-SUN programs

Bundling QUV with targeted diagnostics shortens the loop between finding a weakness and implementing a fix.

Frequently Asked Questions (recap)

What does QUV simulate?

Accelerated UV exposure to reproduce long-term photo-degradation (fading, yellowing, chalking, micro-cracking).

How long should I test?

It depends on material and decision need. We’ll propose a practical hour target with interval checks so you can stop once outcomes are clear.

Can you run side-by-side comparisons?

Yes—supplier colors, coatings, or polymer lots are mounted and evaluated in parallel under identical conditions.

What if exposure reveals a failure?

We can immediately add FTIR/Raman (chemistry) and E-SEM/AFM (micro-structure) to diagnose causes and recommend changes.

How is QUV different from Q-SUN?

QUV isolates UV effects; Q-SUN provides full UV + Visible + IR with humidity control for broader sunlight simulation.

Suggested Internal Links (provisional; finalize later)

- Shelf-life & Product Degradation — Q-SUN (Sunlight + Humidity)

- Thermal Analysis — DSC (Differential Scanning Calorimetry)

- Surface & Morphology — E-SEM / AFM (Micro-cracks & Texture)

- Contact Angle — Wettability & Surface Energy

Contact & CTA

Request a QUV weathering plan or ask for a quote to design the right UV exposure program for your materials. We’ll deliver clear, decision-ready evidence for R&D, QC, supplier control, and customer documentation.Infrastructure Services

National Nanotechnology Center (NANOTEC)

143 INC 2 (B), Thailand Science Park, Phahonyothin Road, Khlong Nueng, Khlong Luang, Pathum Thani 12120

Tel. +66 2 564 7100 ext. 6517, 6625, 6680

Email: bdis-infs@nanotec.or.th