Meta description (140–160): Identify and quantify volatile organics with NANOTEC’s GC-MS and GC-MS/MS services. Headspace sampling supports VOCs in foods, packaging and environment, essential oils, medicinal plant actives, phthalates, naphthalene, and petrochemical hydrocarbons.

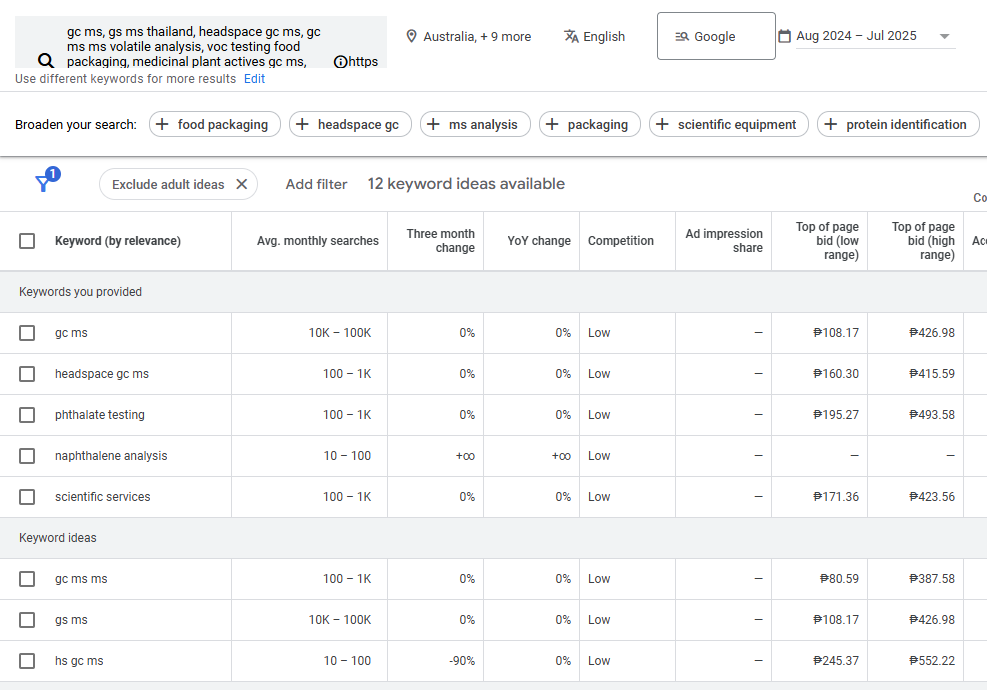

SEO Keywords (one line): gc ms, gs ms thailand, headspace gc ms, gc ms ms volatile analysis, voc testing food packaging, essential oil component analysis, medicinal plant actives gc ms, phthalate testing, naphthalene analysis, hydrocarbons petrochemical, materials and environmental testing Thailand

Why GC-MS Matters

Volatile and semi-volatile organic compounds (VOCs/SVOCs) shape safety, quality, compliance, and consumer perception across industries. A faint solvent note in a beverage, a plastic smell from new packaging, or a lingering off-odor in a cosmetic can lead to product holds and reputational damage. In parallel, compliance drivers—residual solvents, phthalates, naphthalene, selected pesticides, and hydrocarbons—require auditable measurement. For natural products, essential oils and medicinal plant extracts need consistent compositional profiles to prove authenticity and batch-to-batch uniformity.

Gas Chromatography–Mass Spectrometry (GC-MS) is the workhorse that answers the two questions every QA and R&D team asks: What’s present? and How much? GC separates complex mixtures into individual compounds, and MS identifies them by their mass spectra. With Headspace GC-MS, we analyze the vapor above a sample, pulling out volatiles cleanly from complex matrices. When targets are trace-level or matrices are noisy, GC-MS/MS (tandem MS) provides the selectivity and sensitivity to confirm identity and quantify confidently.

At the National Nanotechnology Center (NANOTEC), we combine methodical sample handling with robust chromatographic methods to deliver decision-ready data for foods and packaging, cosmetics and herbal products, environmental and occupational monitoring, and petrochemical/materials workflows.

What We Measure and When to Use Each Mode

GC-MS is a family of approaches. We select the mode that matches your targets, matrix, and decision context.

GC-MS (Full Scan / Selected Ion Monitoring)

- What it does: Separates a mixture by retention time; the mass spectrometer acquires spectra that we match to libraries or reference standards.

- When to use:

- Qualitative profiling (e.g., essential oil composition, aroma fingerprints, off-odor investigations).

- Routine quantitation where co-elution and matrix interferences are limited.

- Strengths: Broad screening capability; excellent for discovering unexpected compounds.

Headspace GC-MS

- What it does: Samples the gas phase above the specimen (solid or liquid) in a sealed vial. Only volatile constituents partition to the headspace—reducing matrix effects and simplifying prep.

- When to use:

- Residual solvents & VOCs in foods, beverages, and packaging (films, closures, inks, adhesives).

- Aroma profiles and off-odor root-cause analysis.

- VOCs in environmental and consumer product matrices where direct injection would be messy.

- Strengths: Clean chromatograms, minimal sample handling, high reproducibility for volatiles.

GC-MS/MS (Tandem MS)

- What it does: Adds a second stage of mass filtering/fragmentation to isolate target ions, boosting selectivity and sensitivity dramatically.

- When to use:

- Trace-level targets in complex matrices (e.g., phthalates in plastics, naphthalene in environmental extracts).

- When regulations or customer specs require unequivocal confirmation using qualifier/quantifier transitions.

- Strengths: Lower limits of quantitation (LOQs), high confidence in the presence/absence of specific analytes.

For non-volatile or thermally labile analytes, we’ll recommend HPLC/LC-MS/MS. For functional group confirmation or polymer identity, see FTIR.

Target Analyte Classes & Typical Matrices

We routinely support targets and matrices like these (representative, not exhaustive):

- Essential oils & herbal actives

- Use case: Composition profiling of natural extracts and fragrances; authenticity checks; batch consistency.

- Examples: Terpenes and oxygenated terpenes (e.g., limonene, linalool, eugenol).

- Pesticides (volatile/semi-volatile subsets amenable to GC)

- Use case: Screen/quantify residues in plant materials, herbal extracts, or environmental samples.

- Phthalates & naphthalene

- Use case: Compliance checks in polymers/films, packaging, consumer goods, environmental extracts.

- Residual solvents & general VOCs

- Use case: Foods and beverages; packaging interactions (inks, adhesives, coatings, closures); consumer product emissions.

- Examples: Ethanol, isopropanol, acetone, toluene, ethyl acetate; odorous aldehydes and ketones.

- Hydrocarbons (petrochemical/materials streams)

- Use case: Composition of process streams, feedstocks, extracts; tracking contaminants that impact downstream yield or performance.

- Environmental/occupational

- Use case: VOCs in air-adjacent matrices or water extracts; investigations around facilities and production areas.

If your target list includes compounds of mixed volatility, we can split the panel (e.g., Headspace for the volatiles; direct injection or derivatization for semi-volatiles), or pivot to LC-MS/MS for the non-GC-amenable fraction.

Method Development, Calibration & Quality

Your decision context determines how we build the method:

- Screening vs. targeted quant. For broad discovery (off-odor, unknown peaks), we start with full-scan GC-MS. For compliance or release, we implement calibration curves with reference standards and switch to SIM or MS/MS as needed.

- Matrix-matched calibration. When matrix effects are likely, we use matrix-matched standards and internal standards to control recovery and precision.

- Confirmation. We confirm IDs with retention time, ion ratios (SIM), or transition ratios (MS/MS).

- Controls & blanks. Solvent blanks, method blanks, and carryover checks are built into runs—especially important for Headspace work and phthalate testing.

Work is performed within NANOTEC’s ISO 9001 quality framework with documented procedures and change control.

Reporting You Can Use

You receive a decision-ready package that stands up to QA review and partner audits.

Typical contents:

- Chromatograms with labeled peaks (targets and notable unknowns).

- Mass spectra (key ions highlighted) and, where applicable, library match metrics.

- Identification table: targets, retention times, qualifier/quantifier ions (or MS/MS transitions), acceptance criteria.

- Quantitation table: concentrations and units, calibration range/fit, and LOD/LOQ if part of the method.

- Method summary: sampling mode (Headspace vs. direct injection), column/temperature program, key MS parameters, internal standards used.

- Interpretive notes: exceedances vs. your limits, likely off-odor drivers, known matrix effects, and next-step recommendations.

If needed, we provide CSV exports for LIMS, and overlay plots for multi-lot comparisons (e.g., aroma profile drift over time, packaging changes).

Instrumentation & Sample Requirements

GC-MS (Agilent GC 7890A – MS 5973C)

- Modes: Direct injection and (as applicable) Headspace GC-MS for volatile matrices.

- Supported sample types & minimum amounts:

- Powders: 10–20 g

- Solids (e.g., films, polymers): 10–20 g (representative cut pieces totaling that mass are acceptable)

- Liquids: 1–5 mL

- Gases: 0.5 L (sealed container or appropriate sampling bag/canister)

- Preparation note: For qualitative direct-injection screening, you may dissolve ~1–5 mg of sample in a suitable organic solvent (we’ll confirm compatibility).

GC-MS/MS Triple Quadrupole (Agilent GC 7890B – MS/MS 7170)

- Use case: Targeted confirmation/quantitation with higher selectivity and sensitivity.

- Supported sample types & minimum amounts:

- Powders: 10–20 g

- Solids: 10–20 g

- Liquids: 1–5 mL

- Preparation note: For qualitative direct-injection screening, you may dissolve ~1–5 mg of sample in an organic solvent (we’ll confirm compatibility).

General submission tips

- Use airtight, clean containers; for phthalates/VOCs, prefer glass and avoid plasticized caps/liners.

- Label matrix and history (e.g., drying, curing, extraction) and provide any target list/spec limits for pass/fail assessment.

- For Headspace work, minimize headspace loss and avoid perfumed or solvent-rich environments during handling.

Turnaround & Scheduling (Updated)

Qualitative analysis (screening/ID; includes Headspace where applicable)

- Lab time: 3 working days (≤10 samples) after your *queue slot is confirmed

- Data files: within 5 working days

- Formal report: within 7 working days

Quantitative analysis (calibrated targets; SIM or GC-MS/MS)

- Lab time: 5 working days (≤5 samples) after *queue confirmation

- Data files: within 7 working days

- Formal report: within 10 working days

*Timelines are counted from the date your test slot is confirmed.

Common Use Cases & Outcomes

- Residual solvent control (food/packaging). A beverage shows a paint-like note. Headspace GC-MS flags ethyl acetate and toluene above spec. Root cause traced to a change in adhesive cure on new labels; supplier corrected cure schedule; off-odor disappears.

- Essential oil authenticity. An EO batch smells “thin.” GC-MS profile deviates from reference chemotype—key oxygenated terpenes are low and markers of adulteration are present. Batch rejected; supplier required to furnish provenance.

- Phthalates in polymer films. Customer spec bans certain phthalates. GC-MS/MS quantification confirms compliance for two, but detects DEHP near the action limit. Supplier change control enacted; procurement updates incoming QC.

- Naphthalene in environmental extract. Investigative sampling near a facility detects naphthalene; MS/MS confirmation meets regulator’s confirmation criteria; mitigation plan launched.

- Hydrocarbon carryover in process stream. An unexpected C9–C12 hydrocarbon pattern appears after a process change; GC shows the profile; process engineering identifies a sealant change as the source and replaces it.

Where GC-MS Fits in Your Workflow

- Incoming QC. Verify that raw materials, extracts, packaging meet VOC/residual limits before release to production.

- Formulation & scale-up. Track aroma profiles, solvent removal, and contaminant carryover as parameters shift.

- Release & compliance. Produce auditable reports for customers and regulators; use GC-MS/MS when confirmation is required.

- Troubleshooting & CAPA. Identify off-notes, unknown peaks, or process-related contaminants quickly so corrective actions are focused and effective.

- Supplier management. Compare lots and negotiate with objective chromatographic data; set realistic acceptance windows.

Who This Service Is For

- Food & Packaging QA/RA. Demonstrate control of VOCs/residuals; investigate off-odors and packaging interactions; document compliance.

- Cosmetics & Herbal Products. Profile essential oils and medicinal plant actives; verify batch consistency; screen for restricted volatiles.

- Environmental & Occupational Monitoring. Assess VOCs in air-adjacent matrices or water extracts with defensible GC-MS or MS/MS.

- Petrochemical & Materials Producers. Quantify hydrocarbons and track stream quality; identify contaminants that reduce yield or performance.

- SMEs & Startups. Start lean with Headspace GC-MS screening; add GC-MS/MS confirmation only when partner/regulatory expectations require it.

- Overseas Customers/Investors. Standardized, clearly annotated reporting to align with cross-border specifications and audits.

Pricing Overview

Use the guide price to scope your program; we’ll finalize a formal quotation based on target list, matrix complexity, calibration strategy, and confirmation needs.

- GC-MS (incl. Headspace as applicable): from THB 3,000 per sample

- Options: GC-MS/MS targeted confirmation/quant; expanded calibration ranges; replicate runs; multi-analyte panels; customized reporting/overlays.

If you’re planning a screening matrix (e.g., supplier × process × storage), we can design a tiered plan that balances coverage, turnaround, and budget.

Frequently Asked Questions

What’s the difference between GC-MS and GC-MS/MS?

GC-MS provides separation, identification, and quantitation for many volatiles. GC-MS/MS adds a second stage of mass filtering, giving higher selectivity and sensitivity—ideal for trace-level targets and complex matrices.

When should I use Headspace?

When targets are volatile (residual solvents, VOCs, aroma compounds) and you want to minimize matrix effects and sample prep. Headspace is particularly effective for foods, beverages, and packaging components.

Can you quantify as well as identify?

Yes. Provide your target list and units/limits, and we’ll implement a fit-for-purpose calibration (including internal standards) and report concentrations with method details.

Which matrices are supported?

Typical matrices include foods, packaging/films, herbal extracts/essential oils, environmental samples, and petrochemical/materials streams. We’ll tailor prep and injection/Headspace to the matrix.

What if targets aren’t amenable to GC?

We’ll recommend HPLC/LC-MS/MS for non-volatile or thermally labile analytes, and coordinate if you want a combined plan.

Suggested Internal Links

- Chemical Analysis — FTIR (Functional Groups & Material ID)

Contact & CTA

Request a GC-MS plan or book a consultation to choose the right approach—Headspace vs. direct injection; GC-MS vs. GC-MS/MS—for your targets and matrix. We’ll deliver clear, auditable data you can act on for release, compliance, or rapid troubleshooting.Infrastructure Services

National Nanotechnology Center (NANOTEC)

143 INC 2 (B), Thailand Science Park, Phahonyothin Road, Khlong Nueng, Khlong Luang, Pathum Thani 12120

Tel. +66 2 564 7100 ext. 6517, 6625, 6680

Email: bdis-infs@nanotec.or.th