Meta description (140–160): Quantify antimicrobial efficacy with NANOTEC’s ASTM E2149 test—dynamic contact method reporting % reduction against specified bacteria for treated materials, coatings, textiles, plastics, and additives.

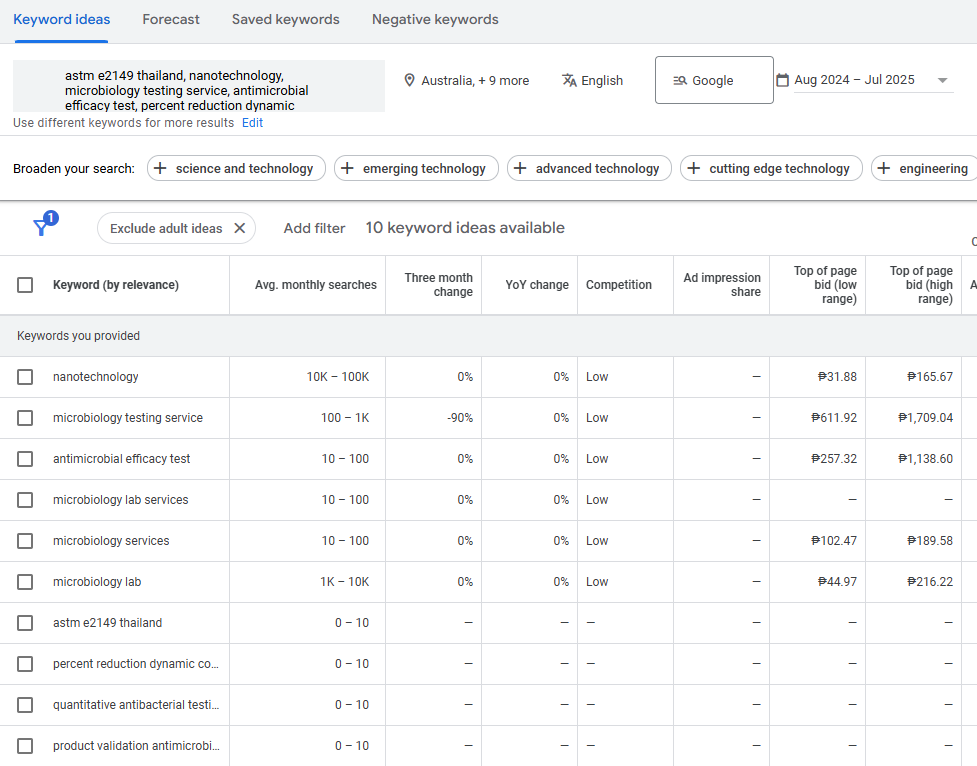

SEO Keywords (one line): astm e2149 thailand, nanotechnology, microbiology testing service, micriobiology services, micriobiology lab, antimicrobial efficacy test, percent reduction dynamic contact, quantitative antibacterial testing, treated textile coating plastic, s aureus e coli test, microbiology lab services, product validation antimicrobial, qa qc antimicrobial agents, materials characterization thailand

Why ASTM E2149 Matters

If your product or additive claims “antimicrobial”, qualitative screens alone aren’t enough. Partners, retailers, and regulators expect quantitative evidence that the treated article inhibits microbial growth under conditions that reflect real use. That is where ASTM E2149 excels. Unlike plate-based clear-zone screens, E2149 exposes the specimen to a well-mixed bacterial suspension under dynamic agitation, ensuring consistent contact between microbes and the treated surface or agent. The result is a percent reduction value (% reduction) compared with an untreated control—a number you can put into specifications, acceptance criteria, and technical data sheets.

The method is particularly useful for non-leaching or contact-active systems (e.g., embedded antimicrobials, immobilized agents on fibers or films) where static diffusion tests may under-represent performance. It also helps separate true surface activity from effects that depend on heavy leaching, giving development and QA teams a clearer picture before scale-up, claims, or audits.

At the National Nanotechnology Center (NANOTEC), ASTM E2149 lives within a complete testing workflow—from screening (AATCC 147 qualitative), to durability (wash/UV/sunlight aging), to chemistry confirmation (e.g., FTIR/GC-MS for finish/additive presence) and surface morphology (E-SEM/AFM for coverage and defects). We help you move from concept to claim with an evidence chain that stands up to scrutiny.

What We Measure: ASTM E2149

Principle. A standardized bacterial suspension is prepared at a defined concentration. Your specimen—treated fabric, coated coupon, plastic part, or a representative form of additive—is immersed in the suspension and agitated for a defined contact time and temperature. After exposure, surviving bacteria are enumerated and compared with an untreated control. The method reports percent reduction (% reduction) versus the control.

Default test organisms (commonly requested):

- Staphylococcus aureus

- Escherichia coli

- Klebsiella pneumoniae

- Pseudomonas aeruginosa

(These align with organisms noted in our microbiology notes; if you require alternatives or a different panel, tell us your target list and rationale.)

Typical outputs you’ll receive:

- % reduction vs. control for each organism at the specified contact time

- CFU counts (starting and post-exposure, control vs. treated)

- Test conditions (e.g., agitation, contact time, temperature)

- Specimen details (format, mass/area, any preconditioning such as wash or aging)

If you also want log reduction for communication or internal thresholds, we can provide a derived value alongside the % reduction.

Where E2149 fits: Use it when you need quantitative, dynamic-contact data to set pass/fail criteria, compare formulations or suppliers, validate durability strategies, or prepare customer/regulatory dossiers.

Planning the Test (Scope, Conditions, and Decision Use)

We’ll scope an exposure plan that reflects your product and decision need:

- Organisms: choose from our default panel or propose a targeted list.

- Contact time: align with realistic use scenarios or industry expectations. [Insert: preferred contact time]

- Temperature & agitation: tuned to method guidance and your material’s practical conditions. [Insert: target temperature]

- Replicates: set to balance statistical confidence and budget.

- Durability steps: optional pre-wash or pre-aging (e.g., QUV/ Q-SUN) if you need to test post-use resilience.

At the end, you get a decision-ready package that can support supplier qualification, R&D down-selection, release checks, or claim substantiation.

Reporting You Can Use

Your report is structured for QA review and partner documentation:

- Results table: % reduction per organism, raw CFU counts (control vs. treated), and replicate data

- Pass/Fail flags: based on acceptance limits you provide (we’ll help translate targets into practical thresholds)

- Method summary: ASTM E2149 dynamic contact, with key parameters (organisms, contact time, temperature, agitation, media)

- Interpretive notes: highlight performance vs. target, material trends (e.g., stronger effect on Gram-positive vs Gram-negative), and next-step recommendations (e.g., durability check or chemistry confirmation)

If you maintain a house template or need bilingual (EN/TH) outputs, we can align the format so it drops into your QMS and customer files cleanly.

Sample Requirements & Preparation (From the Lab Guideline)

Good microbiology starts with good specimens. Please follow the NANOTEC Sample Preparation Guidelines so we can deliver valid, reproducible data on the first pass:

Standard/Test: ASTM E2149 — Standard Test Method for Determining the Antimicrobial Activity of Immobilized Antimicrobial Agents under Dynamic Contact Conditions (Quantitative)

Accepted sample types:

- Powders (e.g., additives, masterbatch granulate milled as needed)

- Solid articles that can be cut into small pieces (e.g., coated coupons, fabric swatches, molded plastic parts)

Minimum quantity:

- ~10 grams per organism (to support replicates and controls), per our lab note

What to send & how to label:

- Provide both treated specimens and untreated controls in the same geometry (to isolate the effect of the antimicrobial agent).

- For powders/additives, consult us on an appropriate test format or carrier before shipping.

- Label specimens clearly (product name, lot, treatment ID, front/back where applicable).

- Handle with clean gloves; avoid fingerprints, oils, and extraneous biocides that could confound results.

History & conditioning:

- Share any pre-wash, curing, or storage details.

- If durability is essential, request pre-wash or pre-aging (e.g., QUV/Q-SUN sunlight/UV) before the E2149 run; send extra material for these steps.

We’ll confirm counts per organism/replicate during scoping so you know exactly how many pieces to prepare.

Turnaround & Scheduling

Microbiology requires continuous laboratory days to maintain incubation and handling discipline. For planning purposes:

- A complete cycle (testing + analysis + report) typically takes ~2–4 weeks from your queue date, excluding public-holiday weeks.

- Incubation and related steps are scheduled in at least four consecutive working days (e.g., Mon–Thu or Tue–Fri). If a holiday interrupts continuity, we will move your start to the next feasible window to protect data integrity.

- If you have deadlines (e.g., customer trials, regulatory filings), tell us at request time so we can advise a realistic start window and draft report timing.

This scheduling discipline ensures the repeatability and defensibility of your data.

Interpreting & Using the Data

High % reduction (e.g., strong inhibition vs. control) typically supports moves to:

- Durability programs (wash cycles, QUV/ Q-SUN exposures) followed by re-testing to confirm persistence.

- Scope expansion: more organisms, broader contact times, or environmental conditions that mirror use.

- Claim language discussions with marketing/RA, backed by quantitative evidence.

Moderate or variable % reduction:

- Consider chemistry confirmation (FTIR/GC-MS) to verify additive presence or detect leachables.

- Use E-SEM/AFM to check surface coverage, uniformity, and defects that influence contact.

- Explore dose–response or processing tweaks (e.g., binder ratios, cure profiles) and re-test.

Low/no % reduction:

- Re-examine specimen format (geometry, surface area to volume) and test time relative to your material’s mechanism.

- Verify finish loading and compatibility with the host matrix.

- Consider a mechanism shift (e.g., from purely contact-active to controlled-release in moisture) if aligned with end-use.

Our team can help translate numbers into practical actions that shorten the loop between finding a weakness and fixing it.

Who This Service Is For

- Textiles, Coatings & Plastics (Corporate / OEM/ODM).

Quantify antimicrobial efficacy on treated fabrics, films, laminates, and molded parts to support supplier control, specs, and release. - Healthcare, Touch Surfaces & Filters.

Assess activity on high-touch components and filter media under dynamic contact closer to real use. - Additive & Masterbatch Suppliers.

Demonstrate dose–response and matrix effects of antimicrobial chemistries in representative substrates to accelerate customer adoption. - SMEs & Startups.

Move beyond qualitative screens to quantitative data that supports claims, partner due-diligence, and funding milestones. - Universities & Research Institutes.

Generate publication-grade quantitative results with clear method detail and organism panels.

Quality & Documentation

Testing is conducted to ASTM E2149 and delivered within NANOTEC’s ISO 9001 quality framework. If you require customer-specific formats, bilingual documents, or additional raw data appendices, we will align to your templates.

Complementary & Follow-On Tests (Build a Defensible Evidence Chain)

- AATCC 147 — Qualitative clear-zone screen for quick go/no-go before quant work

- Durability & aging: QUV (UV) and Q-SUN (full spectrum + humidity), then re-test E2149 to assess persistence

- Chemistry confirmation: FTIR / GC-MS to verify finish/additive presence and check leachables

- Surface morphology: E-SEM / AFM to visualize coverage, defects, and fiber/film interfaces tied to performance

- Safety & toxicology (where relevant to end-use claims)

Together these create a coherent narrative from claim → mechanism → durability → safety that customers and auditors can follow.

Pricing Overview

Scope your program with the guide rate below; we’ll confirm a formal quotation after we lock organism count, replicates, and any pre-treatments:

- ASTM E2149 (dynamic contact, % reduction): from THB 3,000 per sample per organism

- Options: multiple organisms; replicate runs; pre-wash or pre-aging (QUV/Q-SUN) before testing; photo documentation; derived log-reduction summary; bundled chemistry/surface analyses

Ask about panelized studies (e.g., multiple suppliers or formulations) with side-by-side reporting that simplifies procurement and design decisions.

Frequently Asked Questions

How is ASTM E2149 different from clear-zone tests like AATCC 147?

E2149 is quantitative and uses dynamic contact (agitated suspension), reporting % reduction vs. control. AATCC 147 is qualitative, showing presence/absence of a clear zone on agar.

Which bacteria can you test?

Our default set includes S. aureus, E. coli, K. pneumoniae, P. aeruginosa. We can discuss alternatives depending on your claims and feasibility.

What sample amount do you need?

Per our lab guideline, plan for ~10 g per organism, and provide treated + untreated controls in matching geometry. We’ll confirm counts during scoping.

Can you test durability (wash or UV/sunlight) before E2149?

Yes. We can run pre-wash cycles and/or QUV/Q-SUN aging, then perform E2149 to assess persistence of antimicrobial activity.

How long will it take?

End-to-end (testing + analysis + report) typically completes in ~2–4 weeks from queue date, accounting for consecutive lab days and excluding public-holiday weeks.

Suggested Internal Links (provisional; finalize later)

- Microbiological Testing Hub

- AATCC 147 — Qualitative Clear-Zone Screen

- ISO 27447 — Antimicrobial Activity of Photocatalytic Materials

- QUV / Q-SUN — UV & Sunlight Aging

- FTIR / GC-MS — Chemistry & Leachables Confirmation

- E-SEM / AFM — Surface Coverage & Morphology

- Safety & Toxicology Services

Contact Us

Request an ASTM E2149 plan or ask for a quote with your target organisms, contact time, and acceptance criteria. We’ll design a fit-for-purpose program and deliver clear, defendable data you can use for R&D decisions, QA/QC, and partner documentation.Infrastructure Services

National Nanotechnology Center (NANOTEC)

143 INC 2 (B), Thailand Science Park, Phahonyothin Road, Khlong Nueng, Khlong Luang, Pathum Thani 12120

Tel. +66 2 564 7100 ext. 6517, 6625, 6680

Email: bdis-infs@nanotec.or.th