Meta description (140–160): Screen textile materials for antibacterial activity using AATCC 147 at NANOTEC. Qualitative “clear zone” results against S. aureus, E. coli, K. pneumoniae, and P. aeruginosa for fast go/no-go decisions.

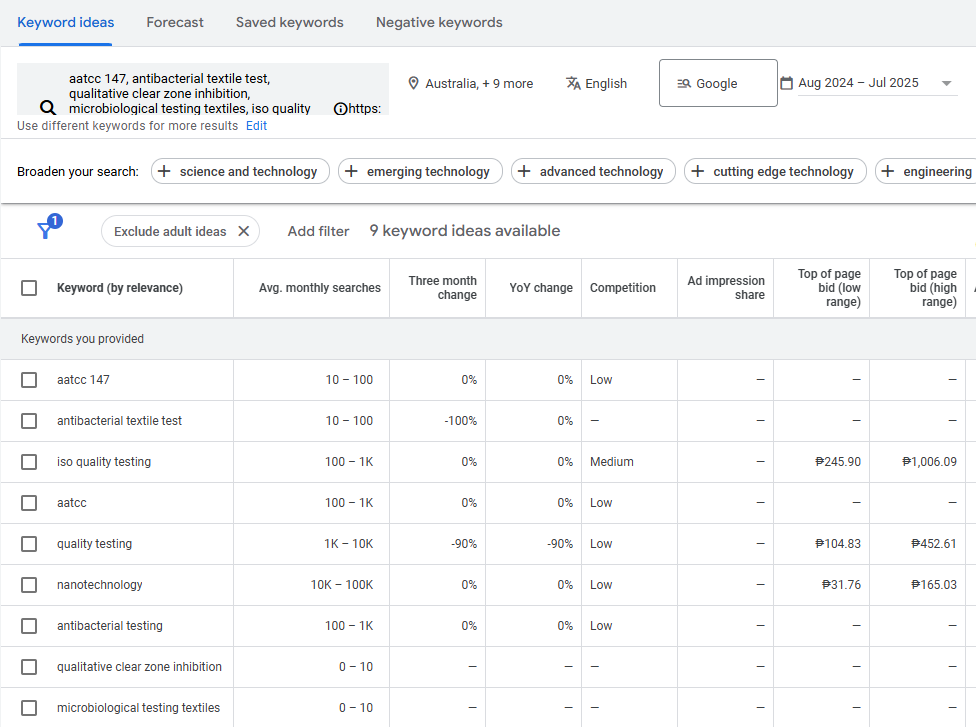

SEO Keywords: aatcc 147, aatcc, nanotechnology, antibacterial testing, quality testing, antibacterial textile test, qualitative clear zone inhibition, microbiological testing textiles, s aureus e coli test, medical textile ppe testing, sportswear odor control test, antimicrobial fabric screening, iso quality testing, materials characterization Thailand

Why This Test Matters

Textile performance today goes beyond colorfastness and hand feel. From hospital gowns and patient bedding to sportswear, socks, and home textiles, antibacterial functionality is increasingly part of the specification and the marketing claim. But not all antibacterial finishes behave the same way once they are applied to a fabric, combined with binders, cured, filled, or laminated. Some finishes leach and inhibit bacteria in the surrounding medium; others rely on contact activity at the fiber surface; some are pH- or moisture-sensitive and only show effects under certain conditions. Before investing in long, quantitative protocols or durability programs, product teams need a fast, defensible screen to answer a simple question: Is there observable antibacterial activity at all?

The AATCC 147 Antibacterial Activity Assessment of Textile Materials: Parallel Streak Method provides exactly that early answer. It is a qualitative, clear-zone test that visualizes whether a textile specimen inhibits bacterial growth on an agar plate. When you need go/no-go evidence, supplier comparisons, or a quick yes/no before moving to quantitative methods, AATCC 147 is the practical starting point.

At the National Nanotechnology Center (NANOTEC), we integrate this screen into a broader evidence chain. If a clear zone appears, we can help you proceed to quantitative tests and durability studies; if it doesn’t, we can investigate root causes using chemical analysis (to confirm finish presence), surface morphology (to see coating coverage), and aging protocols (to check whether UV or storage conditions reduce activity). The goal is to help you make confident decisions with minimal delay and to escalate only when the science—and your timelines—require it.

What AATCC 147 Measures and How It Works

Standard: AATCC 147, Antibacterial Activity Assessment of Textile Materials: Parallel Streak Method (qualitative).

Principle: A standardized lawn of test bacteria is prepared on agar. The textile specimen is laid across parallel streaks of bacteria. After incubation under controlled conditions, the plate is inspected for zones of inhibition (clear areas) adjacent to the specimen.

Result type: Qualitative. Presence/absence of a clear zone—and its observed width—indicates whether the specimen exhibits antibacterial activity under the test conditions. A larger clear area typically reflects stronger leaching or inhibition behavior in the test set-up.

This method is intentionally simple and visual, making it ideal for early screening, supplier comparisons, and internal decision gates. It does not produce a log-reduction value; when you need a numerical reduction under static or dynamic conditions, we will guide you to an appropriate quantitative method (e.g., ASTM or ISO standards) after this first pass.

Test Organisms Covered by Default

For practical relevance across hygiene, odor, and environmental concerns, our default AATCC 147 panel includes the following bacteria:

- Staphylococcus aureus

- Escherichia coli

- Klebsiella pneumoniae

- Pseudomonas aeruginosa

These species represent Gram-positive and Gram-negative organisms commonly referenced in healthcare textiles, protective apparel, and consumer products. If you require other organisms for a particular claim or regulatory pathway, let us know; we can discuss feasibility and scope.

When to Use AATCC 147 (and When to Escalate)

Use AATCC 147 to:

- Screen new finishes during R&D to verify there is any observable antibacterial effect on fabric.

- Compare suppliers or finishes side-by-side before committing to pilot runs.

- Confirm activity after changes in binders, cure profiles, or finishing lines.

- Document evidence for internal gates and early customer discussions.

Escalate beyond AATCC 147 when you need to:

- Quantify antibacterial performance (e.g., log reduction over time).

- Assess durability after washing, abrasion, or UV/sunlight exposure.

- Verify chemistry (finish presence, leachables) or surface coverage that explains weak or inconsistent activity.

NANOTEC can line up the next steps—e.g., a quantitative antibacterial method, QUV/Q-SUN aging followed by re-testing, FTIR/GC-MS for finish verification, or E-SEM/AFM for coating morphology—so you build a coherent, cross-validated record.

Reporting You Can Use

Your report is designed for clear, fast decisions and easy sharing with QA, procurement, and partners:

- Result summary for each organism: Clear zone observed / Not observed (with observed width, where applicable).

- Photographic documentation of plates at endpoint (optional but recommended for supplier/customer communication).

- Method highlights: organisms used, media, incubation time/temperature, plate layout, and any deviations agreed in advance.

- Interpretive note with next-step guidance (e.g., proceed to a quantitative test, consider post-wash evaluation, or investigate chemistry/coverage).

- Appendices (optional): side-by-side image plates for multiple finishes/suppliers, annotated to highlight differences.

Sample Requirements & Preparation (Textiles and Plastics)

Sending representative, well-prepared specimens is the best way to avoid invalid results and re-runs. Please use the following guidance from our Sample Preparation Guidelines:

Accepted materials:

- Textiles: fabric and paper substrates

- Plastics: sheets/films intended for antibacterial claims or contact surfaces

Minimum sizes per test organism:

- Textiles (fabric/paper): half A4 sheet (one piece per organism)

- Plastics: 2.5 × 5 cm coupons, at least 4 pieces per organism

General handling:

- Label clearly (front/back, lot, finish ID, supplier, date).

- Avoid fingerprints, oils, dust, or residues on the test area.

- Provide finish details, cure conditions, and any pretreatments; these help interpretation and repeatability.

- If you plan post-wash or post-aging evaluations, include extra coupons so we can sequence testing without delays.

If your product is a laminate, printed, or coated fabric, mark the exposed side and note any intended use conditions (e.g., moisture exposure), which can influence bacterial interaction in practice.

Turnaround & Scheduling

Microbiological testing requires controlled scheduling to ensure consistent incubation windows and uninterrupted plate work. As a practical planning note:

- A complete cycle covering testing and reporting typically requires ~2–4 weeks from the date your samples enter the lab queue.

- We schedule incubation to occur over at least four consecutive working days. If a public holiday would interrupt that sequence, your test may be moved to the next feasible window to preserve data quality.

- If you are on a strict timeline, please highlight deadlines when submitting your request so we can advise realistic start dates and report targets.

This approach ensures that incubation and observations are continuous, repeatable, and defensible for audits or customer review.

Interpreting Results—and Acting on Them

Clear zone observed: Your finish shows visible antibacterial activity in the AATCC 147 set-up. Next steps often include:

- Durability checks (e.g., post-wash or post-UV exposure) followed by re-testing to confirm the effect persists.

- A quantitative method to generate a log-reduction value appropriate for product claims or regulations.

- Chemistry verification (FTIR/GC-MS) and coverage assessment (E-SEM/AFM) when consistency across lots is critical.

No clear zone observed: The specimen did not inhibit the test organisms under these conditions. Options include:

- Verifying finish presence and distribution (chemical/surface analysis).

- Adjusting finishing parameters (binder ratio, add-on level, cure) and re-screening.

- Considering an alternative antibacterial mechanism (e.g., contact-active vs. leaching systems) or different organism panel aligned to the end-use environment.

Our team can help you interpret the outcome within your application context—odor control in sportswear is a different target than clinical textiles—and propose a fit-for-purpose plan.

Who This Service Is For

Textile & Nonwoven Manufacturers (Corporate / OEM/ODM).

Screen antimicrobial finishes rapidly across suppliers and lines, confirm feasibility before pilot runs, and document early evidence for internal gates.

Medical & Protective Textiles.

Evaluate visible antibacterial activity against common pathogens in early development; then plan biocompatibility, durability, and quantitative follow-ups as needed.

Sportswear & Home Textiles Brands.

Assess odor-related bacterial inhibition on treated knits and wovens to support product positioning and vendor control.

SMEs & Startups.

Use a cost-effective screen to prioritize chemistries and finishing routes before committing to higher-cost validations.

Universities & Research Institutes.

Obtain publication-ready qualitative evidence with optional plate images and method details; escalate to quantitative tests if required by your study design.

Quality Framework

Testing is conducted in line with AATCC 147 procedures and delivered within NANOTEC’s ISO 9001 quality management framework. If your program requires a specific report format, language, or additional documentation, we will align the outputs so they are ready for customer, retailer, or grant files.

Recommended Complementary Methods (Build a Strong Evidence Chain)

- Quantitative antibacterial testing (e.g., dynamic or static log-reduction methods such as ASTM/ISO appropriate for textiles).

- Durability & aging: QUV (UV) and Q-SUN (full spectrum + humidity) exposures, followed by re-testing to check persistence of activity.

- Chemical confirmation: FTIR or GC-MS to verify finish presence, assess potential leachables, or compare supplier chemistries.

- Surface morphology: E-SEM (environmental SEM) and AFM to visualize coating coverage, fiber surface, and defects that influence antibacterial contact.

- Wettability & cleanability: Contact Angle testing to understand how finishing alters surface energy, which can affect bacterial adhesion and soil release.

With these tools in one place, you can move from a yes/no screen to a root-cause narrative and a durability-ready claim efficiently.

Pricing Overview

Use the guide rate to scope your request; we’ll finalize a quotation based on number of organisms, replicates, and documentation options.

- AATCC 147 qualitative antibacterial test: from THB 1,500 per sample per organism

- Options: replicate plates; full photo documentation; pre-/post-wash comparisons; post-aging re-tests (QUV/Q-SUN); bundled chemistry/surface analyses

If you plan to test multiple finishes or suppliers, ask about panelized workflows and side-by-side reporting that make procurement decisions straightforward.

Frequently Asked Questions (recap)

Is AATCC 147 quantitative?

No. It is a qualitative clear-zone method. For log-reduction values, we’ll recommend an appropriate quantitative standard and design the study with you.

Which bacteria are included?

By default: S. aureus, E. coli, K. pneumoniae, P. aeruginosa. Other organisms can be discussed depending on the claim and feasibility.

Can you test washed or aged samples?

Yes. Provide your wash protocol or choose a standard program. We can also perform UV/sunlight aging (QUV/Q-SUN) and then re-test.

What do I need to send?

For textiles: one half-A4 piece per organism. For plastics: 2.5 × 5 cm coupons, ≥ 4 pieces per organism. Label front/back, lot, and finish. We’ll confirm counts during scoping.

Do I get photos of the plates?

Yes—upon request. Photographic documentation is often useful for internal QA and partner communication.

How long does it take?

Plan for ~2–4 weeks from queue date to final report, allowing for consecutive incubation days and any public holidays. We’ll align on practical start dates when scheduling.

Suggested Internal Links (provisional; finalize once all pages are live)

- Microbiological Testing Hub

- ASTM E2149 — Quantitative (Dynamic) Antimicrobial Activity

- ISO 27447 — Antimicrobial Activity of Photocatalytic Materials

- QUV / Q-SUN — UV & Sunlight Aging

- FTIR / GC-MS — Finish & Leachables Confirmation

- E-SEM / AFM — Surface Morphology & Coverage

- Contact Angle — Wettability & Cleanability

Contact & CTA

Request an AATCC 147 test or ask for a quote with your target organisms and any durability steps (wash/aging). We’ll design a practical, defensible screening program and deliver clear results you can use for R&D triage, supplier control, and early customer discussions.

Infrastructure Services

National Nanotechnology Center (NANOTEC)

143 INC 2 (B), Thailand Science Park, Phahonyothin Road, Khlong Nueng, Khlong Luang, Pathum Thani 12120

Tel. +66 2 564 7100 ext. 6517, 6625, 6680

Email: bdis-infs@nanotec.or.th