Meta description (140–160): Validate antibacterial performance of photocatalytic surfaces with NANOTEC’s ISO 27447 test—quantitative results under controlled illumination for TiO₂-based and other semiconducting coatings, films, and ceramics.

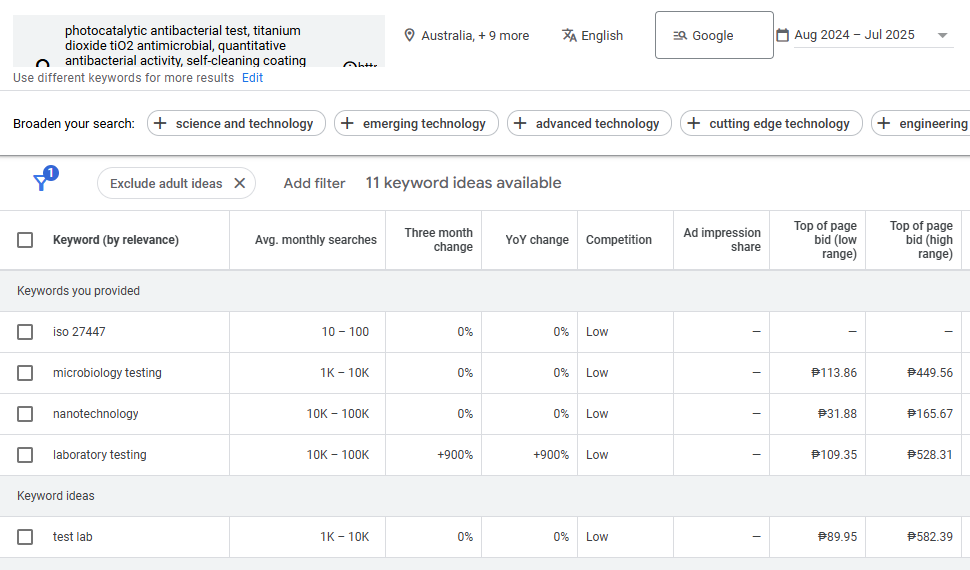

SEO Keywords (one line): iso 27447, microbiology testing,, nanotechnology, laboratory testing, photocatalytic antibacterial test, titanium dioxide tiO2 antimicrobial, quantitative antibacterial activity, illuminated surface test, self-cleaning coating validation, ceramic and glass antibacterial, building materials hygiene, healthcare surface coatings, materials testing thailand

Why ISO 27447 Matters

Photocatalytic surfaces—often based on semiconducting oxides such as TiO₂—are engineered to generate reactive species under light that can inactivate bacteria on contact. These materials show promise in built environments, transportation interiors, public touchpoints, appliances, and healthcare-adjacent applications, where cleanliness, odor control, and perception of hygiene matter. But credible claims demand more than anecdotes or ad hoc experiments. If you want customers and regulators to trust your “self-disinfecting” narrative, you need a standardized method that controls illumination and exposure, and that reports quantitative antibacterial performance.

ISO 27447 delivers exactly that. It is a test method tailored to semiconducting photocatalytic materials, quantifying antibacterial activity under defined light exposure. Results from ISO 27447 let you:

- Compare suppliers and formulations with numbers, not opinions.

- Convert R&D screening into specifications (acceptance limits).

- Demonstrate performance to auditors, buyers, and regulators with a recognized standard.

At the National Nanotechnology Center (NANOTEC), ISO 27447 sits inside a broader characterization ecosystem. When exposure reveals strengths or gaps, we can quickly add durability aging (QUV/ Q-SUN), surface morphology (E-SEM/AFM), and chemistry checks (FTIR/GC-MS) to explain the “why”—so you can adjust and retest without changSing vendors.

What the Test Measures: ISO 27447 (Illumination-Based, Quantitative)

Principle. A standardized bacterial suspension is placed in contact with your photocatalytic specimen (e.g., coated panel, film, tile). The assembly is exposed to a defined light source so that the photocatalyst is activated. After the prescribed exposure time, surviving bacteria are enumerated and compared with appropriate controls (dark/blank), producing a quantitative antibacterial result.

What you receive:

- A quantitative antibacterial outcome, typically expressed as an antibacterial activity value and/or % reduction / log reduction relative to controls.

- Illumination parameters and exposure time clearly documented (critical for photocatalytic mechanisms).

- Specimen details (format, dimensions, surface preparation) and the test organism used.

Commonly tested organisms. In practice, teams often choose a Gram-positive and a Gram-negative representative. Our microbiology capability includes Staphylococcus aureus, Escherichia coli, Klebsiella pneumoniae, and Pseudomonas aeruginosa. If you need other species (e.g., application-specific strains), we can discuss feasibility during scoping.

Because light drives activity, documenting illumination is essential. We align exposure conditions to the standard and discuss any tailoring needed to reflect your use case (indoor lighting vs. daylight-adjacent, UVA vs. broader spectra).

When to Use ISO 27447 (and When to Use Something Else)

Choose ISO 27447 when:

- You’re validating photocatalytic antibacterial claims and need illumination-controlled, quantitative results.

- You want to benchmark suppliers or screen formulations before scale-up.

- You need to translate feasibility into specification limits (e.g., required activity value/log reduction after X hours under defined light).

Consider ASTM E2149 for dynamic contact quantitation of antimicrobial activity not driven by light (e.g., immobilized or contact-active chemistries). Use AATCC 147 as a qualitative clear-zone screen early in development for go/no-go decisions. Add QUV (UV) or Q-SUN (full spectrum + humidity) when you must show durability of antibacterial performance after aging.

Reporting You Can Use

Your report is structured for QA, procurement, and partner review:

- Results table: antibacterial activity value and/or %/log reduction per organism, exposure time, and illumination settings.

- Control data: initial CFU and post-exposure CFU for controls (dark/blank) vs. photocatalytic specimen.

- Method summary: ISO 27447 framework with illumination parameters, sample configuration, temperature/humidity (as applicable).

- Interpretive notes: concise commentary that links outcomes to acceptance criteria or next steps (e.g., “meets target; proceed to durability aging and re-test” / “borderline under indoor-light setting; consider spectrum/intensity alignment”).

If you maintain bilingual templates or require a specific customer format, we can align the output so it drops straight into your technical file.

Sample Preparation & Submission (Follow These to Avoid Re-Runs)

From the NANOTEC Sample Preparation Guideline for ISO 27447:

- Accepted specimen types: plastics, ceramics, steel sheets, rubber—with a smooth, non-porous, non-absorbent surface.

- Dimensions & quantity: ≤ 1 cm thickness; cut to 5 × 5 cm; 6 pieces per organism.

- Controls: Untreated control specimens of the same geometry (≤ 1 cm thick, 5 × 5 cm, 6 pieces per organism) are strongly recommended to improve interpretation.

- Handling: avoid fingerprints, dust, or residues that can mask activity. Pack to prevent surface abrasion.

- Labeling: indicate front/active side, coating ID, lot/batch, and any pre-conditioning steps.

If your plan includes post-aging re-tests (e.g., QUV/ Q-SUN, wash cycles), please send additional specimens so we can run aging and re-measure activity without waiting for a second shipment.

Test Planning & Typical Workflow

We design an exposure program that reflects both the standard and your decision goals:

- Scoping

- Organisms (default or application-specific).

- Illumination conditions tied to standard and use case (e.g., indoor UVA-dominant vs. sunlight-adjacent).

- Exposure duration and inspection points.

- Replicates and controls (dark/blank and untreated).

- Execution

- Controlled light exposure of the inoculated specimen.

- Enumeration of surviving bacteria; documentation of controls.

- Analysis & Reporting

- Calculation of antibacterial activity value and/or %/log reduction.

- Consolidation of CFU data, illumination details, and interpretive notes.

- Optional photo documentation and comparative tables (e.g., multiple suppliers/formulations).

- Follow-Up (Optional)

- Durability: run QUV (UV) or Q-SUN (full spectrum + humidity) on retained specimens; re-test ISO 27447 to measure persistence.

- Root-cause diagnostics if performance is low or variable: E-SEM/AFM (surface coverage/texture), FTIR/GC-MS (chemistry/leachables).

Turnaround & Scheduling Discipline

Microbiology work must run on consecutive laboratory days to ensure valid incubation and handling. For planning:

- A complete cycle (test + analysis + report) typically completes in ~2–4 weeks from your queue date, excluding public-holiday weeks.

- Laboratory steps are booked in at least four consecutive working days (e.g., Mon–Thu or Tue–Fri). If a holiday interrupts continuity, we will move your start to the next suitable window to protect data integrity.

- If you have a launch or audit deadline, tell us up front; we’ll advise a feasible queue date and whether a preliminary summary can support your internal timeline while the formal report is compiled.

This approach yields defensible, repeatable data you can stand behind.

Interpreting Results (From Numbers to Decisions)

- Strong activity (meets/exceeds target):

Proceed to durability—e.g., QUV or Q-SUN aging followed by ISO 27447 re-test—to demonstrate persistence under service-like exposure. Consider side-by-side comparisons (color tones, suppliers, coatings) to lock specifications. - Borderline activity (near threshold):

Examine illumination match to real use (spectrum/intensity), surface cleanliness, and coating uniformity. Add E-SEM/AFM to check coverage and FTIR/GC-MS to verify chemistry or detect leachables that might influence performance. - Low/no activity:

Confirm control behavior, verify photocatalyst loading and activation spectrum, and consider formulation/process adjustments. Use AATCC 147 for a quick qualitative screen on variants before re-running ISO 27447.

Our team can translate outcomes into concrete next steps—reducing the iteration cycle between finding a weakness and fixing it.

Who This Service Is For

- Building & Architectural Materials (tiles, glass, panels).

Demonstrate antibacterial activity under defined illumination to support specifications for hygiene-sensitive spaces (restrooms, public lobbies, healthcare-adjacent areas). - Coatings, Films & Surface-Treatment Providers.

Optimize formulations, benchmark suppliers, and produce audit-ready documentation for B2B customers evaluating hygiene claims. - Healthcare & Public-Touch Surfaces.

Validate illuminated, self-disinfecting surfaces for high-contact environments (rails, handles, lifts, kiosks) where perception and performance both matter. - Appliances, Consumer & Transportation Interiors.

Assess activity on interior trims, liners, bezels, and appliance fronts exposed to ambient or UVA-rich light. - SMEs & Startups.

Convert lab ideas into specification-ready data efficiently; escalate to durability and multi-organism panels as traction grows. - Universities & Research Institutes.

Generate publication-quality quantitative results with controlled illumination and organism panels, suitable for tech-transfer packs.

Complementary & Follow-On Tests (Build a Defensible Evidence Chain)

- QUV (UV) and Q-SUN (full spectrum + humidity) — accelerate aging, then re-test ISO 27447 to measure persistence.

- AATCC 147 — qualitative clear-zone screen for fast go/no-go before running a full ISO 27447 panel.

- ASTM E2149 — dynamic contact, quantitative method for non-photocatalytic antimicrobial systems.

- E-SEM / AFM — visualize coating coverage, micro-texture, and defects that influence activation and contact.

- FTIR / GC-MS — confirm chemistry, assess leachables, and help trace variability to root causes.

Together these steps create a traceable narrative from claim → mechanism → durability.

Pricing Overview

Scope your program with the guide rate below; we’ll confirm a formal quotation once we agree on organism(s), replicates, and any pre-aging steps:

- ISO 27447 (photocatalytic antibacterial, quantitative): from THB 4,700 per sample per organism

- Options: multiple organisms; replicate runs; post-aging re-tests (QUV/ Q-SUN); photo documentation; customized report formats; side-by-side supplier comparisons.

If you’re running a screening matrix (e.g., multiple colors or coat weights), ask about panelized study designs that keep cost and lead-time predictable.

Frequently Asked Questions (recap)

Is ISO 27447 quantitative?

Yes. Results are quantitative under controlled illumination, suitable for specification and comparison.

Which organisms do you use?

We commonly test Gram-positive and Gram-negative organisms (e.g., S. aureus, E. coli). Alternatives can be discussed during scoping.

How critical is the light source?

Essential. Photocatalytic activity depends on illumination. We document spectrum/intensity/exposure per the standard and align with your use case.

Can you check durability?

Yes. Add QUV/ Q-SUN aging, then re-test to evaluate performance retention.

Do I need untreated controls?

Strongly recommended. Controls improve interpretation and make comparisons defensible.

How many specimens should I send?

Per our guideline: 6 pieces per organism for the test material (5 × 5 cm, ≤ 1 cm thick) and 6 pieces of untreated control in the same geometry.

What’s the typical turnaround?

Plan ~2–4 weeks from your queue date for testing + analysis + reporting, accounting for consecutive lab days and excluding holiday weeks.

Suggested Internal Links

- Microbiological Testing Hub

- QUV — UV Accelerated Weathering

- Q-SUN — Sunlight + Humidity Aging

- ASTM E2149 — Dynamic Contact (Quantitative)

- AATCC 147 — Qualitative Clear-Zone Screen

- E-SEM / AFM — Surface & Texture

- FTIR / GC-MS — Chemistry

Contact & CTA

Request an ISO 27447 plan or ask for a quote with your target organism(s), illumination needs, and acceptance criteria. We’ll design a fit-for-purpose program and deliver clear, defendable antibacterial data aligned to photocatalytic use.Infrastructure Services

National Nanotechnology Center (NANOTEC)

143 INC 2 (B), Thailand Science Park, Phahonyothin Road, Khlong Nueng, Khlong Luang, Pathum Thani 12120

Tel. +66 2 564 7100 ext. 6517, 6625, 6680

Email: bdis-infs@nanotec.or.th