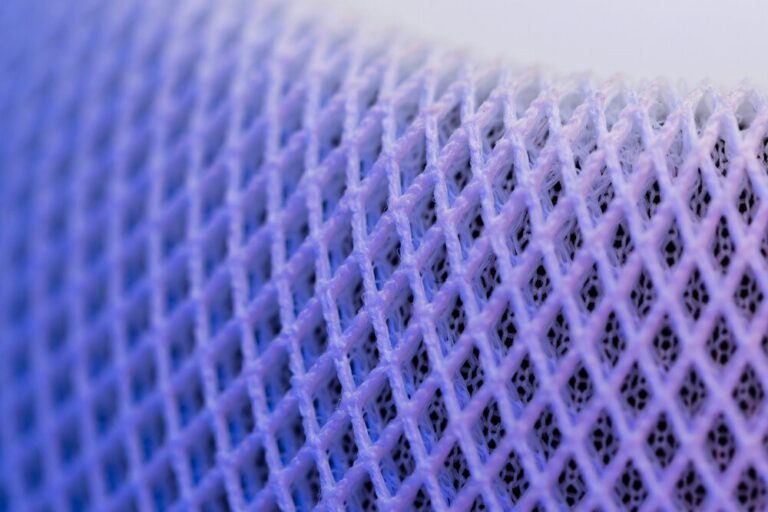

While silicon-based solar cells are one of today’s most promising technologies for generating clean and renewable energy, the devices convert just a fraction of the sunlight that hits the earth into electricity. The high-grade silicon crystals used to make solar cells demand great care during the manufacturing process, resulting in high production costs, limiting the commercialization potential. Researchers have recognized that one way to bring down the cost of these solar cells is to deposit layers of silicon on cheaper substrates such as plastic or glass, but have been stymied by the fact that silicon thin films have lower power conversion efficiencies than bulk silicon crystals because they absorb less light and contain more defects. Now, researchers at the A*STAR Institute of Microelectronics, Singapore, have discovered an approach for increasing the efficiency of silicon thin films deposited on cheap substrates: carve tiny silicon pillars – hundreds of nanometers in size – in the silicon surface. The nanopillars act like a forest of trees, in which light enters but cannot easily get out. Patrick Lo, one of the researchers, said, “When light strikes the surface, it bounces a few more times along or inside the pillars before penetrating the bottom flat surface. Each bouncing event increases the chances of photon absorption.”

http://www.research.a-star.edu.sg/research/6332