Meta description (140–160): Quantify hydrophilic/hydrophobic behavior and surface energy with NANOTEC’s contact angle testing—multi-liquid measurements to guide adhesion, coating, printing, and cleanability decisions across films, polymers, packaging, and electronics.

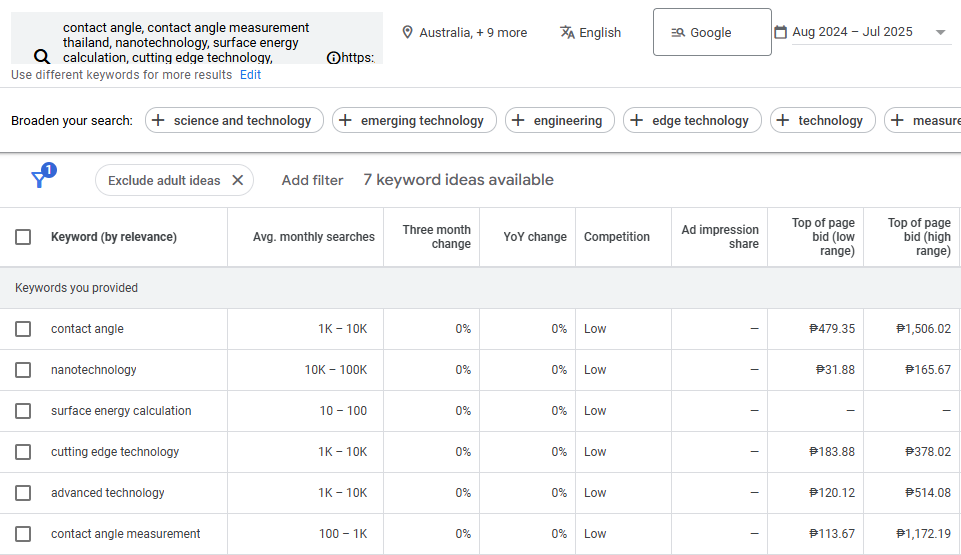

SEO Keywords: contact angle, cutting edge technology, advanced technology, contact angle measurement, contact angle measurement thailand, nanotechnology, surface energy calculation, wettability hydrophilic hydrophobic, multi-liquid contact angle, coatings films adhesion, packaging printability test, cosmetics substrate testing, polymer surface treatment, electronics surface cleanliness

Why Contact Angle Matters

Adhesion, print quality, cleanability, barrier performance, even tactile feel, these are surface-driven outcomes. If a coating beads instead of spreading, if an ink refuses to wet a film, if adhesives lift at edges, or if residues cause smudging, the root cause is often wettability. Contact angle testing provides a direct, quantitative view of how a liquid interacts with your surface: low angles indicate strong wetting (hydrophilic), high angles signal poor wetting (hydrophobic). When you combine contact angle with surface energy calculation, you can match substrates with adhesives, primers, inks, and coatings with far greater confidence, reducing trial-and-error, avoiding rework, and accelerating scale-up.

For regulated or brand-critical products—food and cosmetic packaging, medical device components, printed electronics, contact angle data brings objectivity to decisions that otherwise rely on visual judgment. It helps teams decide which treatment, how much treatment (e.g., plasma/corona), and how long effects persist after storage or converting.

What Contact Angle Measures and When to Use It

Contact angle evaluates the shape of a droplet placed on a surface. The angle at the liquid–solid–air interface reflects how completely the liquid spreads. Using one liquid can answer simple go/no-go questions; using three or more liquids of differing polarity allows calculation of surface energy (often split into polar and dispersive components), which is more predictive across inks, coatings, and adhesives.

Primary outputs

- Static contact angle (per probe liquid) at specified positions/regions

- Calculated surface energy (when ≥3 liquids of different polarity are measured)

Typical probe liquids

- Water (high polarity), representative alcohols (e.g., ethanol, isopropanol), and selected organics chosen to span polarity and surface tension ranges relevant to your process.

Use contact angle to:

- Verify adhesive/coating compatibility and set acceptance limits for incoming substrates.

- Compare surface treatments (plasma, corona, flame, primers) and cleaning protocols (pre/post).

- Troubleshoot print defects (mottling, pinholes, poor laydown) and coating non-uniformity on films or packaging.

- Tune spreadability/feel for cosmetic applicators, wands, and packaging surfaces.

How NANOTEC Delivers Reliable Wettability Data

- NANOTEC operates within an ISO 9001 quality framework and uses validated procedures to ensure repeatability. We align liquid sets and dosing protocols with your actual inks/adhesives where practical, and we document ambient conditions to support like-for-like comparisons over time.

- You receive decision-ready data rather than raw numbers. Results are annotated to highlight uniformity across spots, before/after treatment shifts, and any droplet anomalies (e.g., pinning, absorption) that influence interpretation. If you need a recurring QC scheme, we can formalize test locations, probe liquid sets, and acceptance bands so production teams can apply a consistent standard.

Instrumentation & Sample Requirements

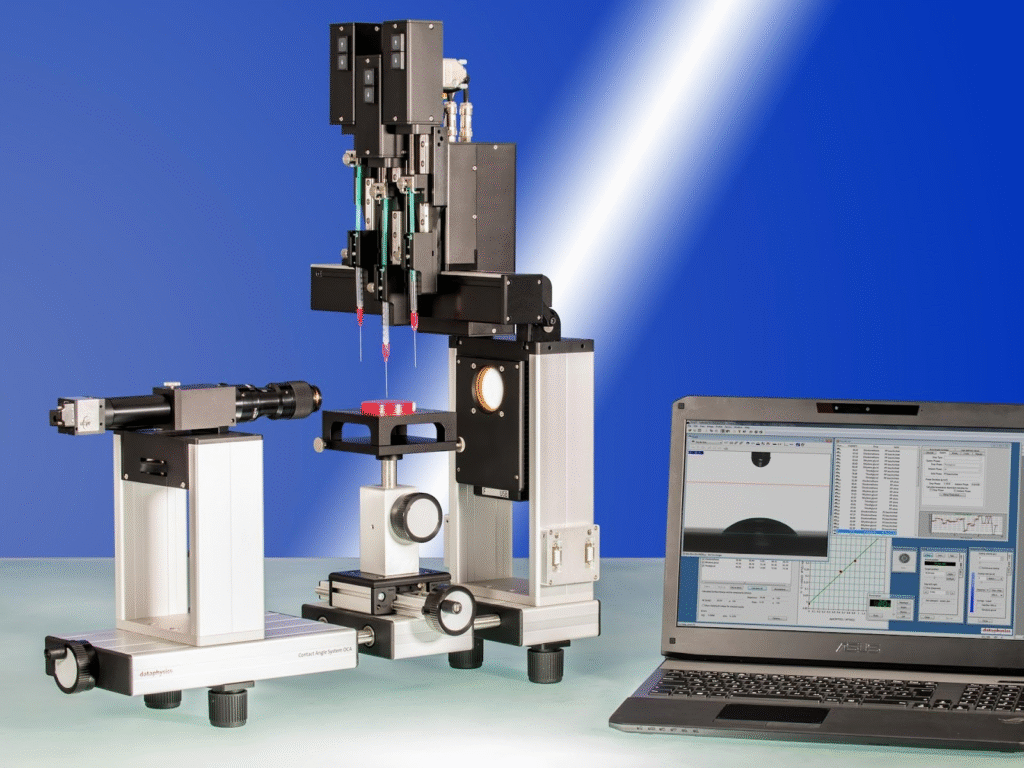

Measurements are performed on a Dataphysics OCA 40 contact angle meter.

- Technique: Static contact angle; multi-liquid surface energy calculation (on request)

- Sample types: Solid substrates including films, glass slides, fibers, coated or uncoated

- Sample size guideline: Width/Length 1–50 cm, Height < 5 cm (thicker items may be accommodated with spacing/fixtures)

- Positioning: Please mark regions of interest (coated side, print zone, edge/center) to ensure consistent measurement placement.

If you use specialized process liquids, share MSDS and handling notes. We will evaluate feasibility or propose a surrogate liquid set that closely mirrors surface tension and polarity.

Reporting You Can Use

A standard NANOTEC report includes:

- Contact angle values (by liquid) at each designated spot/region

- Calculated surface energy (when ≥3 liquids are used), including component breakdown (polar/dispersive) where applicable

- Annotated droplet images and uniformity notes (e.g., mean ± SD across spots)

- Method summary: probe liquids, dosing volume, droplet image capture timing, ambient conditions, and any sample pretreatments

For treatment studies, we provide before/after tables and clear deltas (e.g., “ΔWater angle −18°, surface energy +6 mN/m”), making it simple to set go/no-go thresholds or SOP checkpoints.

Typical Deliverables

- Results table: contact angles per liquid, per spot; surface energy values where calculated

- Annotated photo set (optional): side-by-side droplet images for stakeholder communication

- Variability summary: multi-spot distribution, edge vs. center comparisons

- Interpretive notes: concise guidance linking numbers to adhesion, printability, or cleanability outcomes

Sample Guidance (How to Get Reliable Results)

Cleanliness is everything. Small contaminants create large errors in wetting.

- Avoid fingerprints and oils. Handle samples with gloves; use clean sleeves or petri dishes for storage.

- Flatness/finish. Provide flat or sufficiently smooth regions; macro-roughness can distort droplet geometry. If roughness is inherent, we’ll note implications and adapt placement.

- Mark regions. Indicate coated side, print zone, or critical features so measurements represent real process locations.

- Share treatment/aging history. Plasma/corona effects can decay. Provide treatment time, storage duration, and environment so we can test representative states.

- Porous/absorbent surfaces. Tell us in advance. Wicking alters droplet shape; we’ll adjust timing and analysis, and flag limitations in interpretation.

- Special liquids. If you request non-standard probe liquids, provide compatibility and safety information; we’ll validate dosing and image capture timing.

Consistent sample prep across builds/suppliers ensures that trends reflect materials and processes, not handling differences.

How Teams Use Contact Angle Data

Adhesion & Coating Windows (Films, Polymers, Metals)

Set minimum surface energy targets to ensure primer and topcoat compatibility. Validate that line treatments (plasma/corona/flame) achieve and maintain the required wetting from edge to center and roll to roll.

Printing & Converting (Packaging, Labels, Functional Inks)

Use contact angle and surface energy to prevent mottling, poor laydown, and ink rejection. Compare cleaning protocols and primer chemistries on the actual substrate stack you run (film + primer + ink + overprint).

Cosmetics & Personal Care (Applicators, Packaging)

Tune spreadability and sensorial feel by selecting surface finishes and treatments that deliver desired wetting with water-based or oil-based formulations. Data helps stabilize outcomes across suppliers and colorways.

Electronics & PCB (Dielectrics, Soldermask, Printed Features)

Screen for surface contamination and verify activation prior to deposition or printing. Monitor aging of treated surfaces in storage to decide whether re-treat is necessary before critical steps.

QA, Supplier Management, and Change Control

Embed contact angle/surface energy into incoming QC and change control. When a supplier or process changes, re-check wettability against your acceptance bands to avoid downstream surprises.

Who This Service Is For

- Coatings, Films & Packaging (Corporate & OEM/ODM). Set and verify wetting/adhesion criteria, compare treatments, and resolve print defects with quantitative surface energy data.

- Cosmetics & Personal Care. Optimize spreadability and cleanability on applicators and packaging; confirm treatment steps achieve consistent wettability.

- Electronics & Printed Components. Screen surfaces for contamination and verify activation to improve yield and reliability.

- SMEs & Startups (Materials, Functional Inks). Get fast, practical indicators to guide formulation or surface prep before costly trials or tool time.

Turnaround & Scheduling

- Contact angle testing is efficient to schedule. For routine panels, results are typically available quickly after sample receipt and queue confirmation. If you require multi-liquid surface energy plus before/after comparisons, indicate priorities so we stage spots and liquids for the most decision-critical outputs first.

Pricing Overview

Use the guide price to scope your program; we’ll finalize a quotation based on number of probe liquids, spots/regions, and before/after comparisons.

- Contact angle / surface energy testing: from THB 2,000 per item

- Options: multi-spot mapping, additional probe liquids, before/after comparisons, annotated photo sets

- Bundles: Contact Angle + AFM (roughness/texture), Contact Angle + Nano-Mechanical Tester (durability), Contact Angle + BET (powder surfaces)

Frequently Asked Questions (recap)

What does contact angle tell me?

It quantifies wettability—lower angles indicate better spreading (more hydrophilic), higher angles indicate more hydrophobic behavior.

How is surface energy calculated?

We measure contact angles using at least three probe liquids of differing polarity and apply established models to compute a surface energy value.

Which samples can be tested?

Coatings, films, packaging, polymers, glass, metals, textiles, and treated surfaces. Tell us if the surface is porous or highly rough.

What affects results most?

Surface cleanliness, roughness, and recent treatments. Provide history and handle samples carefully.

Can you compare treatments or suppliers?

Yes—side-by-side measurements and surface energy values make differences clear for QA and procurement.

Suggested Internal Links (provisional; finalize later)

- AFM — Nanoscale Surface Topography

- BET — Surface Area & Porosity (Powders)

Contact

- Book a contact angle session or request a quote for wettability and surface energy measurement. We’ll help you select probe liquids and measurement spots that produce clear, decision-ready data—and, if needed, build a combined plan linking texture, durability, and wettability for robust specifications.

Infrastructure Services

National Nanotechnology Center (NANOTEC)

143 INC 2 (B), Thailand Science Park, Phahonyothin Road, Khlong Nueng, Khlong Luang, Pathum Thani 12120

Tel. +66 2 564 7100 ext. 6517, 6625, 6680

Email: bdis-infs@nanotec.or.th