Meta description (140–160): Measure melting/freezing points, phase transitions, decomposition temperature, enthalpy changes, and specific heat capacity (Cp) with NANOTEC’s DSC service—actionable thermal data for polymers, pharma, food, and cosmetics.

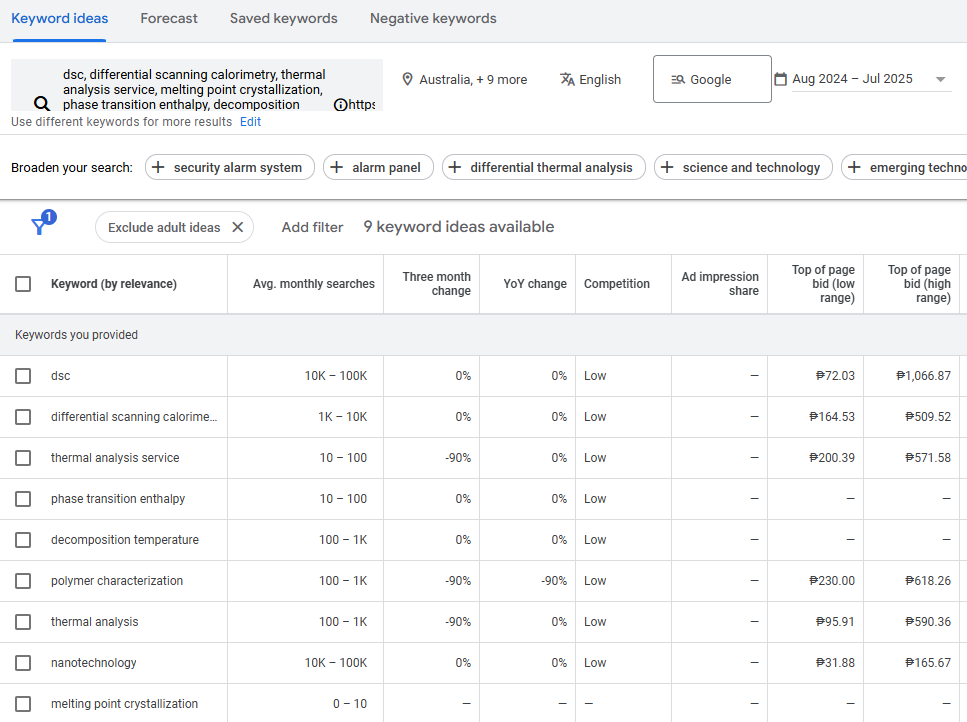

SEO Keywords (one line): dsc, differential scanning calorimetry, thermal analysis service, thermal analysis, nanotechnology, melting point crystallization, phase transition enthalpy, decomposition temperature, specific heat capacity cp, polymer characterization, pharmaceutical thermal behavior, food fat melting profile, cosmetics wax melting

Why DSC Matters

Thermal behavior quietly governs everything from processability to shelf stability. A polymer that softens too early can warp during shaping. A cosmetic base that melts in transit loses texture, oozes oil, and undermines consumer confidence. A compressed tablet that caps or laminates may be signaling a hidden transition or residual solvent effect. In each case, the root cause is often a phase change or thermal event that was never quantified.

Differential Scanning Calorimetry (DSC) turns this uncertainty into evidence. By measuring the difference in heat flow between your sample and a reference during a programmed temperature ramp or hold, DSC reveals melting and crystallization, glass transition, solid–solid transitions, evaporation-related endotherms, and onsets of decomposition. It also quantifies enthalpy (e.g., energy required to melt or crystallize) and can determine specific heat capacity (Cp) under controlled conditions.

For development teams, these readouts anchor realistic process windows and robust specifications. For QA and procurement, DSC provides fingerprints to compare supplier lots or to verify that a change in raw material or storage has not drifted thermal behavior. And because NANOTEC situates DSC within a broader characterization ecosystem, you can connect thermal findings to composition and structure when decisions require a fuller picture—without juggling multiple vendors.

What DSC Measures and When to Use It

Principle. DSC records how much heat your sample needs (or releases) relative to a reference as temperature changes. Endothermic events (like melting) absorb heat; exothermic events (like crystallization) release heat. These appear as peaks or steps in the thermogram, each mapping to a physical or chemical change.

Primary outputs you can request:

- Melting point / melting range and enthalpy of fusion (energy to melt).

- Crystallization (freezing) point and enthalpy of crystallization during cooling.

- Glass transition temperature (Tg) and step height (linked to amorphous phase behavior).

- Solid–solid transitions relevant to polymorphs or semi-crystalline systems.

- Evaporation-related endotherms that can indicate residual solvents or volatiles.

- Decomposition onset temperature (thermal stability indicator under the chosen atmosphere).

- Specific heat capacity (Cp) for energy balance and thermal design.

Use DSC when you need to:

- Define processing windows for mixing, molding, hot-fill, sealing, lamination, or curing—so you heat enough to flow or fuse, but not into degradation.

- Compare suppliers/lots and set acceptance limits using onset/peak temperatures and enthalpies as objective anchors.

- Tune formulations (polymers, wax/fat blends, emulsified bases) for texture, spreadability, and stability across seasons.

- Investigate failures—unexpected softening, oiling-out, delamination, or capping—by checking transitions and decomposition onsets.

- Model heat load in processes or end-use via Cp to size heating/cooling stages and anticipate thermal response.

If mass loss with heating is central (e.g., solvent or moisture), we can coordinate a gravimetric companion method. If a new thermal peak appears and you need chemical context, we’ll recommend the right follow-up from the Chemical Analysis suite.

Instrumentation & Sample Requirements

Instrument

- Differential Scanning Calorimeter: Netzsch DSC 214 Polyma

- Operating temperature range: –20 °C to 350 °C

Supported sample types & minimum amounts

- Powders: ≥ 2 g

- Liquids: ≥ 10 mL

Atmosphere & program parameters (please specify in your request)

- Heating rate: ___ °C/min

- Temperature program (start → stop): ___ °C → ___ °C (add holds/cycles if needed)

- Purge gas: N₂ or Air (select one)

Pan selection & safety

- We’ll choose hermetic or vented pans based on your volatility/pressure risk.

- Disclose any residual solvents, reactivity, or odor so we can set safe conditions

How We Scope and Run DSC at NANOTEC

Every material has its thermal story; our job is to capture it under conditions that mirror your reality.

- Define the decision. Tell us what you must decide—set a sealing temperature, compare two suppliers, confirm a reformulation, or quantify Cp for thermal design.

- Choose the temperature program. We’ll design ramp/hold cycles (heating and cooling rates, number of cycles) to reveal the events you care about without over-processing the sample.

- Atmosphere and pans. Depending on the material, we select an inert or oxidative atmosphere and the right pan type (hermetic for volatiles vs. crimped/vented when pressure build-up is a risk).

- Replicates and overlays. For lot comparison or acceptance work, we typically run replicates and provide overlay plots so differences are immediately apparent.

- Cp determination (on request). We apply a suitable method for specific heat capacity, reporting Cp over your temperature range of interest with the assumptions clearly stated.

All work runs under NANOTEC’s ISO 9001 quality framework with controlled procedures so results are repeatable, reviewable, and ready for partner documentation.

Reporting You Can Use

A strong DSC report doesn’t drown you in graphs—it answers your questions and drops cleanly into QA and technical files.

Typical contents:

- Thermograms (heat flow vs. temperature) with events labeled (Tg, Tm, Tc, decomposition onset).

- Tables of onset and peak temperatures for melting, crystallization, glass transition, and decomposition (as applicable).

- Enthalpies of fusion/crystallization and Cp where requested.

- Comparative overlays (e.g., Supplier A vs. Supplier B; before vs. after aging/extrusion).

- Method summary (pan type, atmosphere, ramp rates, cycle count, high-level instrument settings).

- Interpretive notes—for example, “Processing above X °C risks entering the decomposition region” or “Reduced crystallization enthalpy suggests higher amorphous content; consider cooling profile adjustment.”

If you use a house template or need bilingual headings for internal circulation, we can structure outputs to match.

Sample Guidance (How to Get Reliable Results)

Good DSC begins with representative, well-handled samples and clear context:

- Representativeness. Send enough material to permit repeats or multi-rate scans if comparisons are anticipated.

- Packaging & storage. Minimize exposure to moisture and volatiles; seal samples promptly. Temperature-sensitive materials should be shipped and stored cool if that mirrors real handling.

- History matters. Note any thermal history (drying, curing, annealing, quench) and storage conditions—these often explain variation in Tg or crystallinity.

- Pan selection. If you expect residual solvent or low-boiling components, tell us; we will select hermetic pans or adapt the method to reduce loss artifacts.

- Hazards/sensitivities. Disclose reactivity, odor, or any potential for pressure build-up so we choose safe conditions.

- Targets. Be explicit: “Confirm melting point and enthalpy for spec,” “Compare decomposition onset across three lots,” or “Measure Cp 20–80 °C.”

We’ll check feasibility and finalize a fit-for-purpose program before we start.

Sample Submission Checklist (DSC)

- Decision goal: e.g., confirm Tm/Tg, compare lots/suppliers, quantify ΔH or Cp.

- Program details: fill in heating rate, start/stop temperatures, and gas type (N₂/Air).

- Material & history: note drying/cure/anneal steps and storage; send ≥ 2 g powder or ≥ 10 mL liquid.

- Packaging: seal well; minimize moisture/volatile loss; ship cool if representative.

- Replicates/comparisons: indicate if you want overlays (e.g., A vs. B, pre- vs. post-aging).

Use Cases by Sector

Polymers, Adhesives & Packaging

A heat-seal film shows occasional weak seals. DSC reveals a lower crystallization temperature and a smaller crystallization enthalpy in suspect rolls, consistent with altered cooling on the extrusion line. Process cooling is adjusted; seal strength stabilizes. For an adhesive, DSC confirms cure-related transitions, aligning oven profiles to ensure complete cure without entering decomposition.

Cosmetics & Personal Care

A balm becomes runny in hot climates. DSC maps the melting profile of the wax/oil base and shows a broad endotherm with a low shoulder. Reformulation shifts the blend toward more thermally robust wax fractions; the new DSC profile supports a higher softening window, and sensory tests confirm improved texture retention during shipment.

Food & Nutraceuticals

A confection’s mouthfeel is inconsistent season to season. DSC quantifies the fat melting curve and detects a polymorphic shift after storage. By adjusting tempering and storage temperatures, the manufacturer restores a stable melting profile and consistent texture. In a fortified beverage powder, DSC flags a glass transition near ambient; packaging moisture control is tightened to prevent caking.

Pharma & Medical Materials

A tableting process experiences capping after a supplier change. DSC fingerprints excipient lots and reveals a higher residual solvent signature (evaporation-related feature) and a shifted Tg, affecting compressibility. Supplier acceptance limits are updated; Cp measurements help model heat loads during drying to avoid overexposure.

Advanced Materials & Electronics

A laminated stack experiences warping during reflow. DSC confirms the Tg of each layer and identifies a sub-Tg transition in one adhesive. The stack-up is redesigned to separate critical transitions in the reflow window; decomposition onset data provides a safe cap for thermal excursions.

Who This Service Is For

- Corporate & OEM/ODM (Polymers, Packaging, Adhesives). Establish usable windows for forming and sealing; compare suppliers with objective thermal metrics; support customer audits.

- Cosmetics & Personal Care Brands/Manufacturers. Keep texture and spread consistent; document thermal robustness for distribution in warm climates.

- Food & Nutraceutical Producers. Link fat melting/crystallization to mouthfeel and storage; prevent caking through Tg-aware formulation and packaging.

- Pharmaceutical & Medical Materials Teams. Understand solid-state transitions, excipient compatibility, and thermal stability windows that protect quality.

- SMEs & Tech Startups. Get decisive thermal fingerprints early; scale with confidence rather than trial-and-error.

- Overseas Customers/Investors. Receive standardized, clearly annotated reports suitable for partner review.

Choosing Complementary Methods (When One Curve Isn’t Enough)

DSC explains when things happen; other tools explain what and why.

- Chemical context. If a new thermal event appears or a known one shifts, pair with Chemical Analysis (e.g., FTIR, GC-MS for residuals) to understand the chemistry behind it.

- Structure & surface. If performance changes with morphology, pair DSC with E-SEM (microstructure) or AFM (nanoscale texture).

- Dispersed systems. When your film or coating originates from a dispersion, connect thermal changes to particle size/stability via DLS.

- Wetting/adhesion after heat. If heat treatment affects bonding or printability, confirm with Contact Angle.

We’ll recommend only what your decision truly requires.

Pricing Overview

Use the guide price to scope your program; we’ll confirm a formal quotation based on run length, replicates, and analysis depth:

- Differential Scanning Calorimetry (DSC): from THB 1,200 per hour

- Options: replicate runs; multi-rate scans; comparative overlays (supplier/batch); Cp determination; expanded annotations for audits.

If you need a staged plan (e.g., screen → replicate → Cp), we can phase work to deliver early insights while deeper analyses proceed.

Frequently Asked Questions

What can DSC quantify?

Onset/peak temperatures for melting, crystallization, glass transition, decomposition onset, enthalpy of transitions, and specific heat capacity (Cp).

How much sample is needed?

Loads are typically small, but sending enough for repeats enables comparison and confirmatory scans. We’ll advise practical amounts per matrix.

Can DSC detect subtle formulation changes?

Often yes. Shifts in Tg, Tm, or enthalpies are sensitive indicators of composition and thermal history.

What about volatile samples?

We can use hermetic pans and tailored programs to reduce loss artifacts—please flag expected volatiles or residual solvents.

Can you compare suppliers or lots?

Yes. Overlayed thermograms with summarized metrics make differences clear for QA/procurement and help set acceptance limits.

Suggested Internal Links (provisional; finalize later)

- Thermal Analysis — DSC (this page)

- Shelf-life & Product Degradation Testing — Q-SUN Method

- Shelf-life & Product Degradation Testing — QUV UV Method

Contact Us

Request a DSC plan or book a consultation to design a fit-for-purpose thermal analysis program. We’ll deliver clear numbers and practical guidance you can use in R&D, QC, supplier control, and customer documentation.Infrastructure Services

National Nanotechnology Center (NANOTEC)

143 INC 2 (B), Thailand Science Park, Phahonyothin Road, Khlong Nueng, Khlong Luang, Pathum Thani 12120

Tel. +66 2 564 7100 ext. 6517, 6625, 6680

Email: bdis-infs@nanotec.or.th