National Science and Technology Development Agency | National Nanotechology Center

Research

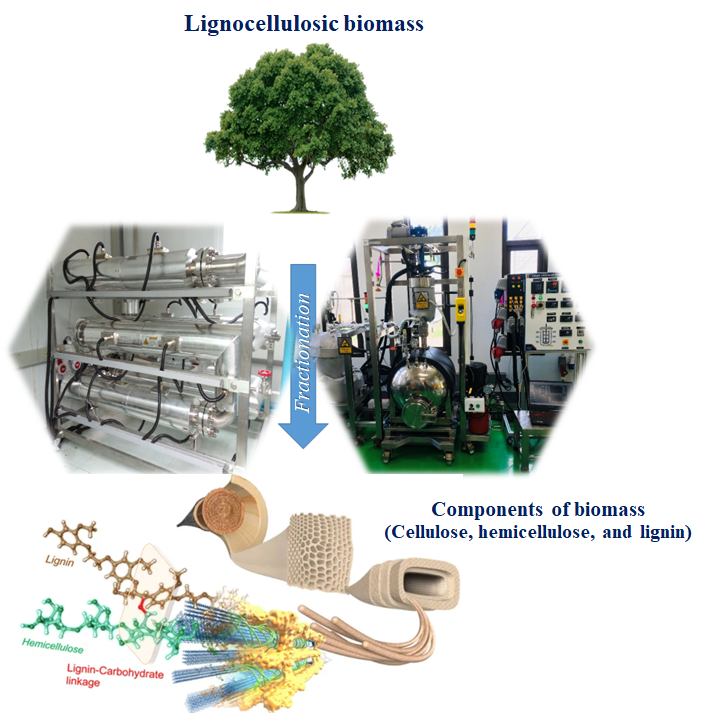

Fractionation and nanocarbons

Biomass is composed of three main components: cellulose, hemicellulose and lignin. These must be separated and isolated for subsequent processing methods suitable for each component. We focus on the development of cost-effective and scalable fractionation processes via chemical and physicochemical pretreatments. We have built liter-scale steam explosion reactors for the lab scale and continuous-flow liquid hot water reactors for the pre-pilot scale.

Several analytical tools are available in-house or nearby labs for exhaustive biomass characterizations:

- CHNS analyzers to determine elemental compositions

- High-performance liquid chromatography for sugar analysis

- Muffle furnaces for ash content analysis

- UV-Vis spectrophotometer for acid-soluble lignin (ASL) analysis

- FT-IR spectroscopy for identification of functional groups

- SEM for morphological studies

- Bomb calorimeter for energy content determination

Additionally, we are capable of analysis of the following standards related to biomass:

- ASTM

- NREL

ACTIVATED CARBON

With the vast agricultural biomass wastes available in Thailand and elsewhere, these wastes can be upgraded by carbonization and functionalization to form activated carbon products. These activated carbons are industrially important for chemical purification, gas purification and environmental applications. We work on the controlled synthesis and functionalization of activated carbon to obtain the materials with high surface areas (> 2000 m2/g), desired pore sizes and rich functionalities (doped with nitrogen or metal nanoparticles).

Tested applications of our materials include:

- Drinking water treatment

- Wastewater treatment

- Organic contaminants removal

- Anti-bacteria

- Heavy metal and cationic contaminants removal

- Battery

Additionally, we are capable of the following measurements related to activated carbon analysis:

- Butane activity

- BTEX adsorption

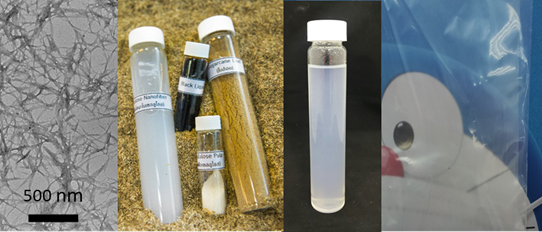

NANOCELLULOSE

Nanocellulose is a naturally derived material produced by the separation of cellulose strands either by chemical or mechanical processes. Its nanostructure imparts unique properties such as dispersibility in water and mechanical properties that can be utilized in packaging, automotive, food & beverage, and healthcare sectors. We work on direct cellulose fractionation from biomass technology to produce cellulose nanofibers (CNF) with nanometer-sized in diameter and several microns up to a hundred micron in length on a pre-pilot scale. We modify these cellulose nanofibers to graft functionalities and fine-tune their physical, chemical, and mechanical properties for desired applications.

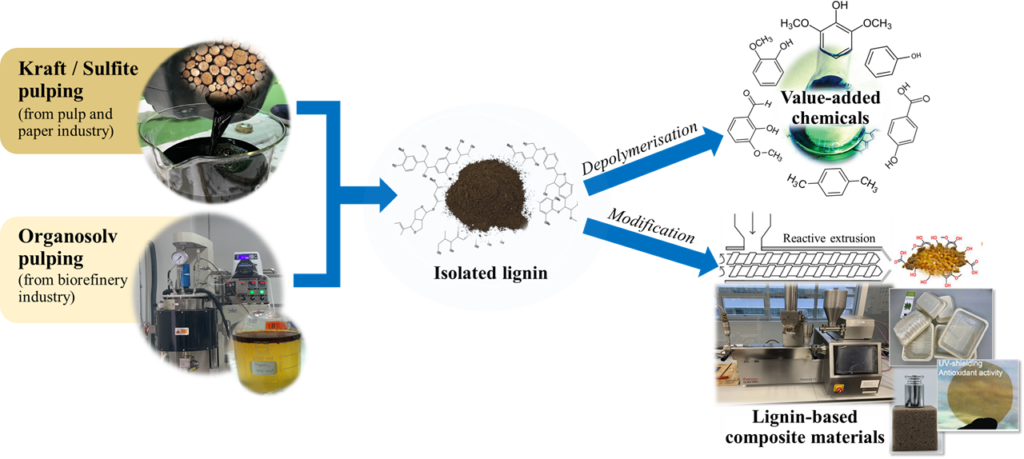

LIGNIN

Due to the phenolic structure of lignin, it can be blended with other materials to yield the properties such as enhanced mechanical strength, antioxidant, UV adsorption and antimicrobial activities. We are working on the process for extraction, isolation, and depolymerization of lignin on a liter-scale reactor. These lignins are then modified and functionalized using physical and chemical processes for compositing with other materials and producing lignin-based chemicals. Several techniques are routinely used to elucidate the structure and thermal properties of lignin including 31P-NMR, 2D-HSQC NMR, Py-GCMS, ATR-FTIR, Mannich reaction, GPC, DSC, and TGA.