National Science and Technology Development Agency | National Nanotechology Center

Research

Separation

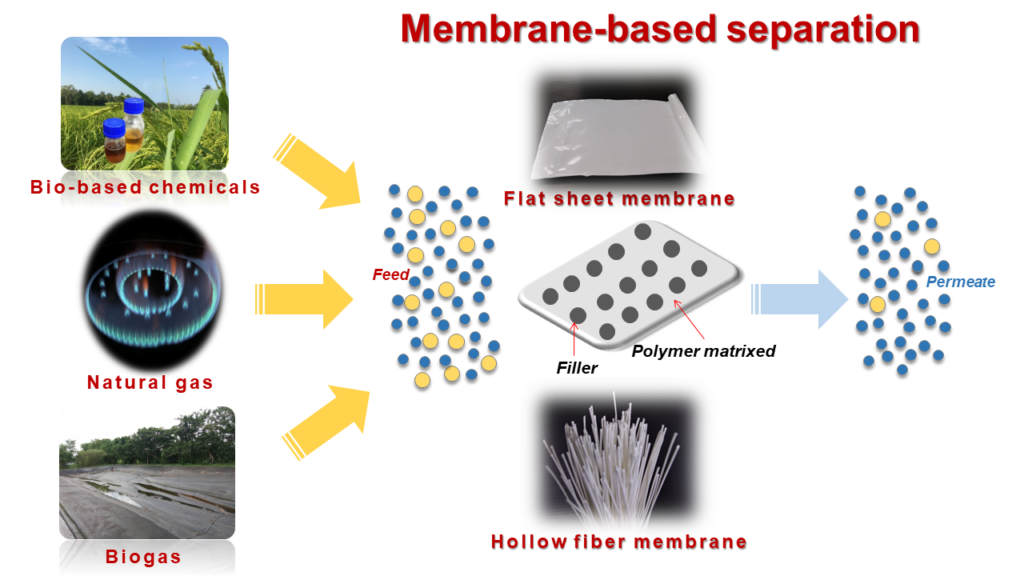

Membranes is an attractive separation technology due to their versatility, high energy efficiency, and small-footprints. The separation performance relies on the affinity of membrane materials to the desired products. Our group focuses on the development of tunable membrane composites containing nanomaterials i.e. MOF, zeolite, carbon nanofiber, and carbon nano-sheet in both flat sheet and hollow fiber forms for gas separation and pervaporation.

For gas separation, we develop membranes specific to CO2 separation for biogas upgrading and natural gas sweetening. Our system supports a pressure up to 50 bar. We also engage in membrane design for gas dehydration and adsorption.

For pervaporation, which is a separation of organic mixtures or organic and aqueous phase, we focus on the development of hydrophobic membranes for a selective separation of bio-based platform chemicals such as furfural. This process can be combined with a reactor in a reaction-separation hybrid process that can improve an equilibrium-limited reaction.